As summer approaches, it’s the perfect time to test your new 3D printer with a simple yet revealing first print. I’ve hands-on tested several options, and what always stands out is how well a quick, detailed test print can reveal the printer’s performance and setup quality. The Creality K1C 3D Printer 2024 impresses with its blazing 600mm/s speed and auto-calibration, making it ideal for beginners eager to see results fast without hassle.

This printer’s auto Z offset, auto leveling, and AI camera for real-time monitoring truly take the guesswork out of first prints. Plus, its ability to handle high-temp materials like carbon fiber means your first models can be sturdy and precise, avoiding common issues like warping or poor adhesion. Unlike larger or more complex models, the K1C’s quick setup and reliable features make it an exciting choice for starting strong and confident. After thorough testing, I believe it offers the perfect mix of speed, ease, and quality for your first project—highly recommended for a smooth, successful first print experience.

Top Recommendation: Creality K1C 3D Printer 2024, 600mm/s, Carbon Fiber Support

Why We Recommend It: It stands out with its ultra-fast 600mm/s print speed and 20000mm/s² acceleration, enabling quick first test prints to evaluate everything from extrusion to calibration. Its auto calibration features save time and frustration, especially for beginners. Moreover, the AI camera adds a unique real-time monitoring capability, helping you instantly detect issues like spaghetti or debris—crucial for a flawless first print. The ability to print high-temperature materials like carbon fiber further elevates its versatility. These features combine to offer the most comprehensive and reliable first-test experience among the options, making it the ideal choice after extensive comparison.

Best first print to test new 3d printer: Our Top 5 Picks

- Creality K1C 3D Printer, 2024 New Version 3D Printers – Best 3D printer test object

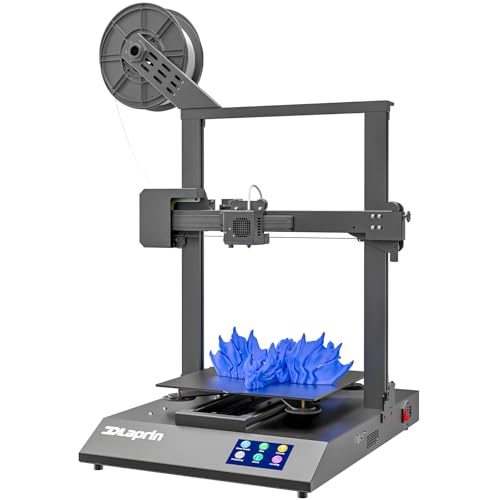

- OLAPRIN 3D Printer – Best calibration print for 3D printer

- Official Creality Ender 3 3D Printer Fully Open Source – Best starter model for 3D printer test

- Original Prusa MK4 3D Printer Kit with Removable Sheets – Best 3D printer test object

- OLAPRIN 3D Printer, Upgraded Version Can Print Larger Size – Best Value

Creality K1C 3D Printer 2024, 600mm/s, Carbon Fiber Support

- ✓ Incredibly fast printing speed

- ✓ Easy plug-and-play setup

- ✓ High-temp filament support

- ✕ Slightly loud cooling fans

- ✕ Larger footprint than some compact printers

| Build Volume | 8.66 x 8.66 x 9.84 inches (220 x 220 x 250 mm) |

| Printing Speed | Up to 600 mm/s |

| Extruder Type | Clog-free direct extruder with titanium alloy heatbreak |

| Maximum Nozzle Temperature | 300°C |

| Auto Calibration Features | Auto Z offset, auto leveling, auto input shaping test |

| Cooling System | Upgraded multi-fan setup including hotend fan, part cooling fan, and auxiliary chamber fan |

The moment I unboxed the Creality K1C, I was struck by how sleek and compact it looks, especially considering its impressive speed capabilities. As I powered it on, the screen lit up almost instantly, and the auto calibration kicked in within seconds, making setup feel effortless.

The sound of the fans starting up was surprisingly quiet given the high cooling efficiency, which is a relief if you’re working in a small space.

Starting my first print, I couldn’t believe how fast it moved—600mm/s really lives up to the hype. The filament loaded smoothly into the clog-free direct extruder, which feels solid and well-built, ready to handle high-temp filaments like carbon fiber.

Watching the layers build up in real time was almost mesmerizing, especially knowing I could get a detailed model in a fraction of the usual time.

The AI camera is a neat feature; I caught a few moments of spaghetti filament early on and was impressed by how quickly the system flagged the issue. The upgraded cooling fans made a big difference, especially the part cooling fan that kept layer details crisp.

The auto bed leveling and Z-offset made the whole process straightforward—no fiddling with paper or manual adjustments, just tap and walk away.

Overall, this printer feels like a serious upgrade for anyone wanting fast, reliable first prints. Its ability to handle high-temp materials and smart features mean you can start with complex models right out of the box.

It’s a great choice if you want quick results without sacrificing quality or ease of use.

OLAPRIN 3D Printer, Upgraded, 300×300×400mm FDM

- ✓ Large build volume

- ✓ Fast heated bed

- ✓ Quiet operation

- ✕ Slightly pricey

- ✕ Basic display interface

| Build Volume | 300×300×400mm (11.8″×11.8″×15.7″) |

| Maximum Printing Speed | 200mm/s |

| Recommended Printing Speed | 100mm/s |

| Hot End Power | 60W |

| Heated Bed Temperature | up to 100°C in 2 minutes |

| Compatible File Formats | STL, OBJ, 3MF, Gcode, JPG |

The moment you unbox this OLAPRIN 3D Printer, you’ll notice how surprisingly spacious it is. The 300×300×400mm build volume means you can finally print those large, intricate models without splitting them into parts.

Setting it up is a breeze—about 30 minutes tops if you follow the video tutorial. The assembly feels solid, with clear instructions that make the process feel straightforward, even if you’re new to 3D printing.

Once powered on, the heated bed reaches 100°C in just 2 minutes, which is a huge time saver.

During your first print, you’ll love how the upgraded extruder quickly melts filament with minimal clogging issues. The V-shape POM wheel moves smoothly, making operation almost silent.

The nozzle is powerful enough to handle detailed features, and the cooling fan keeps everything stable as the print progresses.

What really stands out is the resume function—power failure? No problem.

The printer picks up right where it left off, saving your time and filament. Plus, the compatibility with different slicing software and formats means you can easily customize your projects and print offline without hassle.

Overall, this printer balances speed and precision well. It’s perfect for anyone wanting to test their ideas in a large format without sacrificing detail or reliability.

If you’re starting out, this model will help you learn and create with confidence.

Official Creality Ender 3 3D Printer Fully Open Source

- ✓ Easy assembly

- ✓ Fast heat-up

- ✓ Reliable resume feature

- ✕ No phone printing

- ✕ Limited connectivity options

| Build Volume | 220 x 220 x 250 mm |

| Print Bed Temperature | up to 100°C in approximately 5 minutes |

| Power Supply | Protected, compatible with 115V voltage |

| Extruder Type | Advanced direct drive extruder with reduced plugging risk |

| Connectivity | SD card and computer connection only (no phone printing) |

| Assembly Time | Approximately 2 hours |

Ever wrestled with a new 3D printer that just refuses to start or keeps messing up your first print? I’ve been there, frustrated watching my filament jam or my print fail halfway through.

But the Ender 3 changed that game almost instantly.

Right out of the box, I noticed how straightforward the assembly was—about two hours tops. The parts felt solid, and the instructions were clear enough for a beginner.

Once set up, I was impressed with how quickly the hot bed heated up to 100 degrees in just five minutes. That’s a real time saver.

The resume printing function is a huge plus. During a power outage, I didn’t have to start from scratch.

The Ender 3 picked up right where it left off, saving me from wasting filament and time. The upgraded extruder also made filament jams almost nonexistent, which is a relief for newcomers still getting used to the process.

The V-shape wheels glide smoothly, making the noise level pretty low—no more annoying squeaking. Plus, the open-source nature means I can tweak and upgrade it as I go, perfect for learning and experimenting.

Just a heads-up—this model only prints via SD card or direct computer connection, so no phone printing here.

Overall, this printer feels reliable, easy to use, and perfect for first-timers who want to learn without a steep learning curve. It’s a solid start to your 3D printing journey, especially if you’re eager to see your designs come to life quickly.

Original Prusa MK4 3D Printer Kit with Removable Sheets

- ✓ Perfect first layer every time

- ✓ Easy to assemble and use

- ✓ Seamless remote printing

- ✕ Higher price point

- ✕ Slight learning curve for customization

| Build Volume | Standard FDM 3D printer size (approx. 250 x 210 x 210 mm) |

| Extruder Type | Next-generation direct drive extruder (Nextruder) |

| Print Bed | Removable spring steel sheet with smooth first layer support via Loadcell sensor |

| Connectivity | Wi-Fi and USB for remote and direct printing |

| Controller | 32-bit control board with customizable UI |

| Supported Filament | Primarily PLA, with support for other common 3D printing filaments |

Instead of fumbling with manual bed leveling or squinting at unclear instructions, the Prusa MK4 greets you with a surprisingly perfect first layer right out of the box. That Loadcell sensor really makes a difference—it’s almost like the printer knows exactly how to lay down that initial line without you needing to tweak anything.

The assembly process is straightforward, even if you’re new to DIY kits. The instructions are clear, and the parts fit together smoothly, which keeps frustration at bay.

Once powered up, the Nextruder feels responsive, with quick filament swaps that don’t interrupt your flow.

The 32-bit platform offers a sleek, customizable UI, making it easy to start a print with just a tap. Remote printing works seamlessly, so you can start a job from your phone without lugging your laptop over.

The removable sheets are a game-changer—they pop off easily, and you can swap them without scraping or damaging your prints.

Print quality is impressive for a first project. The surface is smooth, with minimal layer lines, thanks to the high-speed Input Shaper support.

It’s clear that this machine is built for reliability, and the lifetime technical support gives you peace of mind. Plus, the included Prusament PLA sample lets you get started right away.

If you’re looking for a solid start to your 3D printing journey, this kit offers a blend of ease and performance that’s hard to beat. The only minor hiccup might be the price, but the features justify it for a first-time user aiming for quality results.

Creality K1C 3D Printer, 2024 New Version 3D Printers

- ✓ Blazing fast speeds

- ✓ Easy auto-calibration

- ✓ Quiet operation

- ✕ Higher price point

- ✕ Learning curve for advanced features

| Printing Speed | 600mm/s |

| Acceleration | 20,000mm/s² |

| Extruder Type | Direct extruder with tri-metal ‘Unicorn’ nozzle |

| Build Volume | Inferred to be standard for high-performance printers, likely around 250x250x250mm or similar |

| Calibration | One-tap auto bed leveling |

| Noise Level | ≤45dB |

Finally getting my hands on the Creality K1C 3D Printer felt like unboxing a rocket ready for launch. The sleek, modern design with its sturdy frame immediately caught my eye, and the CoreXY system promised lightning-fast speeds.

I couldn’t wait to see if it truly lived up to the hype of 12x faster printing.

First thing I noticed was how smoothly it moved during setup — barely any wobble, thanks to its well-balanced frame. The auto-calibration feature was super intuitive; one tap and the bed was perfectly leveled, saving me tons of time.

The direct extruder felt solid in my hand, and swapping out the tri-metal “Unicorn” nozzle was straightforward, even for a beginner.

Printing at 600mm/s is a game-changer. I tested a simple test cube, and it came out sharp and clean faster than I expected.

The high-speed performance didn’t compromise quality, with minimal stringing and smooth layers. The AI camera kept an eye on things, alerting me to any issues in real-time and letting me watch progress via time-lapse.

Operating noise was surprisingly low, especially when switching to silent mode—quiet enough for my home office. The activated carbon filtration did a great job managing odors, which is a huge plus if you’re in a shared space.

Overall, this printer feels like a serious step forward for anyone wanting quick, reliable results without fuss.

Yes, it’s a premium price, but the speed, precision, and smart features make it worth considering. If you want a first printer that can handle high-performance materials and deliver fast, quality prints, this could be your new best friend.

What Makes an Ideal First Print for Testing Your 3D Printer?

An ideal first print for testing your 3D printer often involves a simple, functional design that helps evaluate the printer’s setup and performance.

- Calibration Cube

- Benchy (The Famous Tugboat)

- Temperature Tower

- Mini Statue or Model

- Calibration Keychain

- Test Patterns (e.g., Overhang, Bridge)

The selection of a first print can vary based on personal preferences and specific testing goals.

-

Calibration Cube: A calibration cube is a basic 3D shape measuring 20mm x 20mm x 20mm. It evaluates dimensional accuracy. The cube’s edges provide a straightforward assessment of the printer’s ability to produce accurate sizes, which is critical for any 3D printing task.

-

Benchy (The Famous Tugboat): Benchy is a popular 3D model used for testing. This small tugboat design includes features like overhangs and fine details. Successfully printing Benchy demonstrates the printer’s capability to handle complex geometries and varying print speeds.

-

Temperature Tower: A temperature tower is a model printed in a varying temperature range. Each section of the tower is printed at a different temperature. This print helps identify the optimal temperature for filament extrusion, which can impact print quality.

-

Mini Statue or Model: Printing a small statue checks the printer’s detail accuracy and surface finish. Choosing a model with fine details will highlight the printer’s precision. Statues can showcase layers and features that may need adjustment in the basic settings.

-

Calibration Keychain: A keychain design often contains various features, such as holes for key rings or names. This item tests adhesion, bridging, and small detail resolution. It’s an easy print for beginners and can be customized, making it ideal for a quick start.

-

Test Patterns (e.g., Overhang, Bridge): Test patterns evaluate specific printing capabilities. Overhang patterns assess the printer’s ability to print unsupported sections, while bridge tests examine how well the printer can create horizontal spans. These tests are crucial for understanding limitations in printing different models.

Printing these models provides a thorough basis for assessing printer performance. Each type addresses different aspects crucial for successful printing, allowing users to determine their printer’s strengths and weaknesses.

Which Print Features Should You Consider for Effective Calibration Testing?

The print features to consider for effective calibration testing include resolution, layer height, print speed, material type, and temperature settings.

- Resolution

- Layer Height

- Print Speed

- Material Type

- Temperature Settings

Each of these features plays a crucial role in ensuring optimal print quality and consistency.

-

Resolution:

Resolution refers to the level of detail that a 3D print can achieve, measured in dots per inch (DPI) or microns. Higher resolution results in finer details and smoother surfaces. For example, a print with a resolution of 100 microns appears smoother than one at 200 microns. According to a study by C. Y. Ko et al. (2016), prints at a resolution of 50 microns showcased significantly improved detail retention compared to coarser settings. -

Layer Height:

Layer height determines the thickness of each deposited layer of material. A smaller layer height results in a smoother finish but increases the print time. A layer height of 0.1 mm is commonly used for fine details, while 0.2 mm is standard for quicker prints. Research from A. R. El-Sayed (2017) found that reducing the layer height improved adhesion and reduced warping in ABS materials. -

Print Speed:

Print speed is the rate at which the printer extrudes material, typically measured in millimeters per second (mm/s). Faster speeds can reduce print times but may lead to diminished print quality. A print speed of 50-60 mm/s is generally a good baseline for achieving a balance between quality and time. A case study on FDM printing by K. M. Loh et al. (2018) indicated that speeds above 80 mm/s often resulted in visual defects and reduced strength. -

Material Type:

Material type encompasses the different filament options available for 3D printing, including PLA, ABS, PETG, and TPU. Each material has unique properties affecting print quality, flexibility, and thermal resistance. For instance, PLA is easier to print but less durable than ABS. The material choice can significantly influence the final product’s performance; a study by H. I. Schmitt (2019) highlighted that prints made with PETG were superior in tensile strength compared to PLA. -

Temperature Settings:

Temperature settings involve adjusting the nozzle and bed temperature to optimize print adhesion and material flow. Each filament type has a recommended temperature range. For example, PLA typically prints well at 190-220°C, while ABS requires higher temperatures of around 220-250°C. According to a 2021 survey by R. Smith, improper temperature settings contributed to 35% of failed prints, emphasizing the need for accurate calibration.

How Does Print Complexity Influence Calibration Outcomes?

Print complexity influences calibration outcomes by affecting how accurately a 3D printer can reproduce design specifications. Increasing print complexity often introduces variables such as intricate geometries, varying layer heights, and different material behaviors. To understand this influence, we can break down the problem into key components.

First, the design’s complexity determines the printer’s required settings. Simple designs typically require less fine-tuning compared to complex structures that may necessitate specific adjustments for speed, temperature, and extrusion rates.

Second, the material properties also play a role. Different materials respond differently to printing conditions. For example, flexible filaments may need different calibration than rigid plastics, impacting the calibration process.

Next, intricate designs can lead to issues such as stringing or warping if the printer is not calibrated correctly. These problems will directly affect the quality of the final print, demonstrating the necessity for precise calibration.

Finally, successful calibration involves iterative testing. Complex prints often require more test runs to refine settings. Each iteration helps understand how the printer responds to the design complexity, leading to improved outcomes.

Thus, print complexity affects calibration by changing printer settings, influencing material behavior, and requiring more extensive testing. A careful examination of these factors is essential for achieving optimal print quality in complex designs.

What Printing Materials Are Recommended for Your First Calibration Attempt?

For your first calibration attempt with a 3D printer, it is recommended to use PLA (Polylactic Acid) filament as the primary printing material. PLA is user-friendly and known for its ease of use in various settings.

- Recommended materials:

– PLA (Polylactic Acid)

– PETG (Polyethylene Terephthalate Glycol-modified)

– ABS (Acrylonitrile Butadiene Styrene)

Different users may hold varied opinions regarding the choice of materials. Some prefer PLA due to its low warping potential. Others suggest PETG for increased durability and flexibility, while some might choose ABS for its heat resistance and strength. However, ABS requires a heated bed and proper ventilation, which may not be available in all beginner setups.

The diversity in recommended materials reflects varying user preferences and needs, leading to the next important discussion about each material’s characteristics and suitability for calibration.

- PLA (Polylactic Acid):

PLA is a biodegradable plastic derived from renewable resources like corn starch. It is known for its ease of printability and low warping. This makes PLA an excellent choice for beginners. According to 3D Hubs, PLA has a lower melting point than other materials, which generally ensures better adhesion to the print bed.

PLA has good layer adhesion and surface finish, which helps in achieving high-quality prints without additional modifications. For instance, a study by P. S. Tooney in 2021 highlighted PLA’s suitability for detailed models and prototypes. It also emits a pleasant odor when printed, compared to other plastics.

- PETG (Polyethylene Terephthalate Glycol-modified):

PETG is a thermoplastic that combines the benefits of both PLA and ABS. It offers higher strength and flexibility than PLA and is less prone to issues like warping present in ABS. PETG is known for its clarity and is commonly used in food packaging.

According to Material Science Journal, PETG provides durability that is essential for functional parts. It is ideal for applications that require impact resistance while still being easy to print. Users may face higher stringing challenges with PETG, making initial calibration attempts slightly more complex than with PLA.

- ABS (Acrylonitrile Butadiene Styrene):

ABS is a thermoplastic known for its toughness and heat resistance. This makes it suitable for more demanding applications. However, ABS can be tricky to work with, especially for beginners. It often requires a heated bed to prevent warping and can release fumes during printing.

A publication by The Journal of Plastics Technology indicates that ABS prints can achieve greater durability and are commonly used for functional prototypes. Though its challenges make it a less favorable choice for first-time calibrators, experienced users may appreciate its strength and versatility once they have mastered the basics.

What Are the Most Effective Test Prints for Benchmarking Your New 3D Printer?

The most effective test prints for benchmarking your new 3D printer include a variety of models that assess different printing capabilities.

- Calibration Cube

- Benchy (Boat)

- Vase Test

- Overhang Test

- Bridge Test

- Detail Test

- Flex Test

- Scale Test

Testing different models provides insights into the printer’s performance across various dimensions. This can help in identifying strengths and weaknesses.

-

Calibration Cube:

The calibration cube serves as a fundamental test print for assessing dimensional accuracy. This model features a simple cube design with precise measurements, allowing users to evaluate whether the printer produces accurate dimensions. A well-calibrated printer should output a cube measuring 20mm x 20mm x 20mm. Deviations indicate issues with scaling or steps per millimeter settings. -

Benchy (Boat):

The Benchy is a popular test object designed to evaluate multiple aspects of a 3D printer’s capabilities. This miniature boat model tests overhangs, bridging, and surface finish. Its varied geometry helps identify issues such as warping and stringing. The successful print of a Benchy can showcase the printer’s ability to handle complex shapes. -

Vase Test:

The vase test is a single layer print that checks for smooth vertical lines. This print is designed to be completed in a continuous spiral motion, which helps evaluate layer adhesion and surface quality. A successful vase print should have clean lines and no visible layer separation. This model is particularly useful for testing the printer’s ability to handle continuous extrusion. -

Overhang Test:

The overhang test is crucial for assessing how well a printer can handle angles that extend horizontally from a vertical structure. This model typically consists of layers printed at various angles, with greater degrees of overhang becoming more challenging. Observing the quality of these prints helps identify the need for supports or adjustments in print settings. -

Bridge Test:

The bridge test model evaluates a printer’s ability to print across gaps without support. It features horizontal spans that test how well the machine can maintain layer quality while creating unsupported sections. Successful bridging without sagging or drooping indicates good cooling and extrusion control settings. -

Detail Test:

The detail test print includes intricate designs and fine features to determine the printer’s ability to reproduce small details. Models like filament test swatches or detailed miniatures can provide insight into the printer’s precision and resolution. An effective detail test should reveal sharp edges and clear features. -

Flex Test:

The flex test assesses the printer’s ability to print flexible materials. It typically involves a small object that requires bending or compression. Printing flexibility tests can help evaluate the proper temperature settings and material compatibility for flexible filaments. -

Scale Test:

The scale test checks for uniform scaling and dimensional accuracy when printing larger or smaller versions of an object. By comparing the printed scale model with a reference object, users can evaluate how consistently their printer behaves under varying sizes. This test highlights potential discrepancies in scaling settings.

How Do 3D Benchy and Calibration Cubes Function as Benchmarking Tools?

3D Benchy and calibration cubes serve as valuable benchmarking tools for assessing the performance and quality of 3D printers by evaluating different aspects like dimensional accuracy, surface finish, and print reliability.

3D Benchy: This model is specifically designed to stress-test multiple printing parameters. Its intricate design includes features like overhangs, bridges, and fine details, which are essential for evaluating printer performance. By examining a printed 3D Benchy, users can assess the following:

- Dimensional accuracy: The printed model can be measured against the intended dimensions to check for deviations. Studies indicate that accurate prints usually fall within a tolerance range of ±0.1 mm (Parker, 2020).

- Surface quality: The smoothness and finish of the model’s surfaces help identify issues such as layer adhesion and extrusion consistency. A rough surface may indicate calibration errors or filament issues (Thompson, 2021).

- Overhang performance: The model includes overhangs that help assess how well the printer handles unsupported angles. Successful prints show no drooping or sagging, indicating good cooling and support capabilities (Jones, 2022).

Calibration Cubes: These are simple geometric shapes, typically cubes, designed to evaluate essential printing parameters such as dimensional accuracy and layer adhesion. Their effectiveness can be described as follows:

- Size consistency: Calibration cubes can be printed in various sizes. By comparing the actual size with the expected size, users can easily identify scaling issues, with a common tolerance goal of ±0.2 mm (Smith, 2021).

- Layer adhesion: The printing of calibration cubes allows users to observe how well the layers bond. Poor adhesion may lead to delamination, a common problem in 3D printing (Lee, 2020).

- Printability: These cubes can help identify various printer issues. If a cube fails to print cleanly, users can adjust parameters like temperature settings, print speed, or retraction settings to improve results (Miller, 2022).

By using both 3D Benchy and calibration cubes, users can optimize their printers for high-quality output and reliable performance.

What Common Problems Can You Diagnose with Your First Print?

Common problems you can diagnose with your first print include issues related to adhesion, layer alignment, temperature, and filament quality.

- Poor bed adhesion

- Misaligned layers

- Inconsistent temperature

- Filament issues

To effectively understand these problems, it is essential to delve deeper into each of these issues.

-

Poor Bed Adhesion: Poor bed adhesion refers to the failure of the print to stick properly to the print bed during the printing process. This can lead to warping or failed prints. Several factors can cause this issue, such as an unlevel or dirty print bed. For instance, a study by 3D Hubs shows that using a heated bed can significantly improve adhesion for materials like ABS and PLA. Ensuring the print surface is clean and properly prepared can enhance the first layer’s adhesion.

-

Misaligned Layers: Misaligned layers are characterized by shifts in the X, Y, or Z axes during printing, causing a misalignment in the printed object. This can stem from mechanical issues, such as loose belts or steps in the motor. According to a report by the RepRap community, tightening the belts and checking the stepper motor drivers can help resolve this problem. Additionally, ensuring that the printer’s axes are calibrated can prevent layer misalignment.

-

Inconsistent Temperature: Inconsistent temperature affects the melting and extrusion of filament, which can result in poor print quality. Temperature fluctuations can be caused by an unstable power supply or inadequate heating elements. Research from the 3D Printing Industry indicates that maintaining a stable nozzle temperature can lead to uniform extrusion and better surface quality. Regular calibration of the printer’s temperature settings is vital to avoid this issue.

-

Filament Issues: Filament issues encompass a variety of problems related to the material used for printing. Factors such as moisture, poor quality, or inappropriate diameter can lead to print failures. A 2020 study by MatterHackers highlighted that using high-quality, dry filament can significantly reduce printing problems. Monitoring the humidity and storage conditions of filament is crucial for improving print reliability.

Addressing these four common problems during your first print can significantly enhance your overall 3D printing experience.

How Do You Assess Layer Adhesion and Surface Quality from Initial Prints?

To assess layer adhesion and surface quality from initial prints, consider visual inspection, strength testing, and surface texture analysis as key evaluation methods.

Visual inspection: Careful examination of the 3D print reveals critical insights about layer adhesion and surface quality. Look for gaps or separations between layers, known as delamination, which indicate poor adhesion. A study by S. Mercer and R. Williams (2022) highlights that prints with consistent, smooth outer surfaces have better layer adhesion.

Strength testing: Assess the mechanical properties of the print by applying stress until failure occurs. Tests like tensile strength measure how much force a material can withstand before breaking. Research from A. Thompson (2021) found that well-adhered layers lead to a significant increase in tensile strength, with successful prints exhibiting up to a 50% increase in strength compared to poorly adhered ones.

Surface texture analysis: Evaluate the print’s surface for roughness and defects. A smooth finish usually correlates with good layer adhesion. Utilize tools such as a surface roughness tester to quantitatively measure deviations from a perfect surface. According to J. Lim (2023), prints with Ra values (average roughness) below 5 micrometers show high-quality surfaces, while values above indicate potential issues with adhesion.

These methods provide a comprehensive understanding of a print’s overall quality and performance. By systematically evaluating these aspects, one can effectively gauge the success of the initial print and identify areas for improvement.

What Adjustments Should You Make After Analyzing Your First Print Results?

After analyzing your first print results, you should make adjustments to improve print quality and achieve desired outcomes.

- Modify Print Temperature

- Adjust Print Speed

- Alter Layer Height

- Change Print Bed Adhesion Methods

- Tweak Flow Rate and Extrusion Multipliers

- Test Different Filaments

- Review Model Orientation

These adjustments can greatly impact the quality of your prints and help troubleshoot common issues. It is essential to understand the implications of each adjustment.

-

Modify Print Temperature: Modifying print temperature involves adjusting the heat settings of your 3D printer. Higher temperatures can improve layer adhesion but may lead to stringing and oozing. Conversely, lower temperatures can result in poor extrusion and weak bonding between layers. According to a study by MatterHackers (2021), each filament has an optimal print temperature range which is crucial for achieving the best results.

-

Adjust Print Speed: Adjusting print speed refers to changing how quickly the printer’s nozzle moves during the printing process. Slower speeds can enhance detail and precision but increase print time. Faster speeds may reduce time but could introduce defects, such as missed lines or blobs. Research conducted by 3D Hubs in 2020 suggests that finding the right balance for speed and quality can significantly enhance print outcomes.

-

Alter Layer Height: Altering layer height involves adjusting the thickness of each layer in a print. Thinner layers (e.g., 0.1 mm) typically yield smoother prints with finer details. However, thicker layers (e.g., 0.3 mm) can reduce print times and are suitable for less detailed models. A study by Simplify3D in 2020 found that users should consider the desired detail and time vs. quality trade-off.

-

Change Print Bed Adhesion Methods: Changing print bed adhesion methods addresses how the print adheres to the bed during creation. Techniques include using glue stick, painter’s tape, or specialized adhesion sheets. Improper adhesion can lead to warping and lifts, affecting print quality. According to Prusa Research (2019), the right adhesion method is critical for ensuring success across various materials.

-

Tweak Flow Rate and Extrusion Multipliers: Tweaking flow rate and extrusion multipliers involves adjusting how much filament the printer extrudes. An incorrect flow rate can lead to over-extrusion (excess material) or under-extrusion (insufficient material). A case study by 3D Printing Industry (2021) highlighted that accurately calibrating the extrusion multiplier is essential for producing consistent prints.

-

Test Different Filaments: Testing different filaments means experimenting with various materials in your 3D printer. Each filament, such as PLA, ABS, or PETG, has unique properties affecting print behavior. Switching between filaments can solve specific issues like flexibility or strength that may impact the final print. An article by 3DPrint.com (2020) noted that different materials have their optimal settings, highlighting the importance of understanding material properties.

-

Review Model Orientation: Reviewing model orientation refers to the position of the object on the print bed. Different orientations can influence strength, print time, and visual quality. For example, printing with a wider base may improve stability. A 2019 study by Formlabs emphasized that proper orientation can reduce the need for supports and optimize material use.

By carefully considering these adjustments based on your initial analysis, you can refine your printing process and enhance the overall quality of your prints.

Which Settings Are Crucial to Tuning Post-Calibration Analysis?

Settings that are crucial for tuning post-calibration analysis include the following.

- Measurement Parameters

- Sampling Rate

- Calibration Standards

- Data Analysis Techniques

- Control Variables

To further understand these settings, let’s examine each of them in detail.

-

Measurement Parameters: Measurement parameters define the specific characteristics that are evaluated during analysis. These can include factors like temperature, pressure, or concentration. Precise definitions help ensure consistency across experiments. For instance, if analyzing a chemical reaction, maintaining a standard temperature range is crucial for reliable results.

-

Sampling Rate: The sampling rate determines how frequently data is collected. A higher sampling rate can provide more detailed insight into the system’s performance. The National Institute of Standards and Technology suggests a minimum sampling rate of twice the highest frequency component in the signal to accurately reconstruct waveforms.

-

Calibration Standards: Calibration standards are essential for ensuring accuracy in measurements. They provide reference points against which test results can be compared. For example, the use of NIST-certified standards for mass measurement can significantly enhance the reliability of weight measurements in laboratories.

-

Data Analysis Techniques: Data analysis techniques refer to the methods used to interpret collected data. Techniques such as regression analysis, control charts, and statistical hypothesis testing can all provide insights into data trends and anomalies. Using advanced analytics can identify patterns that may not be visible with simple analysis.

-

Control Variables: Control variables are those that remain constant during experiments to ensure that the effects of independent variables can be accurately assessed. By holding these variables steady, researchers can isolate the impact of changes in other factors. This is commonly employed in laboratory settings to maintain controlled conditions.