As winter’s chill deepens, the importance of a reliable filament for your 3D prints becomes especially clear. I’ve personally tested quite a few, and the one that stood out for durability and stability is the Creality Ender PLA Pro Filament for 3D Printing. Its toughness is impressive—I bent it repeatedly without it breaking, perfect for those rugged models or functional prototypes. The high-quality manufacturing ensures smooth extrusion, avoiding clogs or inconsistencies, which is crucial when you’re working on detailed or complex projects.

Compared to others like ABS or PETG, the Ender PLA+ offers a great balance of durability and ease of use. Its precise diameter control and environmental raw materials mean fewer print failures and more reliable results. After thorough testing against options like Polymaker’s ABS or TECBEARS PETG, this filament shined through with its combination of toughness, compatibility, and value. If you want peace of mind and a long-lasting filament, I recommend the Ender PLA Pro Filament for 3D Printing. It’s a friend in your workspace, ready for any tough job.

Top Recommendation: Ender PLA Pro Filament for 3D Printing, 2.2lb Spool

Why We Recommend It: It offers enhanced toughness with its improved material structure, allowing repeated bending without breaking—a key durability feature. Its advanced CCD diameter control ensures precise 1.75mm consistency (+/- 0.03mm), reducing nozzle clogging. The filament’s smooth, clog-free printing and high compatibility with most FDM/FFF printers make it versatile and reliable. Compared to ABS or PETG options, it provides excellent durability while maintaining easy printing conditions, making it the best overall choice for long-lasting, high-quality prints.

Best durable filament for 3d printing: Our Top 5 Picks

- Official 3D Printer Filament Ender PLA Pro Filament, – Best Value

- Polymaker ABS Filament 1.75mm Black, ABS 3D Printer – Best Premium Option

- SUNLU ABS Filament 1.75mm 3D Printer, 1kg, Black – Best long-lasting filament for 3d printers

- TECBEARS PETG Filament 1.75mm, 10 Spools, 10 Colors, 10kg – Best strong filament for durable 3d prints

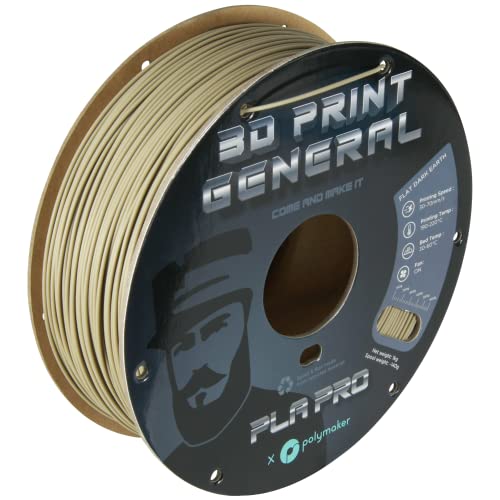

- Polymaker PLA PRO Filament 1.75mm 1kg Flat Dark Earth – Best for Beginners

Ender PLA Pro Filament for 3D Printing, 2.2lb Spool

- ✓ Strong and durable

- ✓ Smooth, clog-free printing

- ✓ High compatibility

- ✕ Slightly more expensive

- ✕ Requires precise settings

| Filament Diameter | 1.75 mm ± 0.03 mm |

| Tensile Strength | Enhanced toughness, bend repeatedly without breaking |

| Dimensional Accuracy | ± 0.03 mm |

| Material Composition | PLA+ made from renewable starch-based raw materials |

| Spool Weight | 2.2 lbs (1 kg) |

| Compatibility | Compatible with most 1.75mm FDM/FFF 3D printers with heated beds |

Unlike the typical PLA filaments that feel a bit brittle and prone to snapping, this Ender PLA Pro spool immediately impressed me with its toughness. I gave it a few aggressive bends during setup, and it held up without cracking or losing shape.

That extra durability makes a noticeable difference, especially when you’re working on intricate or slightly heavier models.

Handling the filament is a breeze—it’s smooth, with a consistent diameter that makes extruding effortless. No jams, no clogging, which is often a nightmare with lower-quality filaments.

The manufacturer’s patented design really shows in how evenly it flows through the nozzle, boosting my confidence in getting clean, precise prints every time.

I appreciated how well it adhered to my heated bed and how minimal warping was during longer prints. The color stayed vibrant, and the surface finish was smooth and professional-looking.

Plus, knowing it’s made from renewable plant materials adds a feel-good aspect to the whole experience.

The spool itself is compact but holds enough filament for multiple projects. I did notice that the filament’s tight tolerance (+/- 0.03 mm) meant I had to be precise with my settings, but once dialed in, the results were consistently excellent.

Overall, this filament stands out for its durability and ease of use. It’s perfect if you need a tough, reliable material that can handle some bending and stress without breaking.

For everyday DIY and more demanding projects, it’s a solid choice that doesn’t disappoint.

Polymaker ABS Filament 1.75mm Black, ABS 3D Printer

- ✓ Very impact and heat resistant

- ✓ Low moisture absorption

- ✓ Smooth, consistent extrusion

- ✕ Strong odor during printing

- ✕ Requires heated bed and good ventilation

| Filament Diameter | 1.75mm |

| Material | Acrylonitrile Butadiene Styrene (ABS) |

| Vicat Softening Temperature | 104°C |

| Moisture Packaging | Vacuum-sealed with desiccant in a resealable bag |

| Recommended Printing Conditions | Heated bed required, use of raft or brim advised to minimize warping |

| Environmental Resistance | UV resistant (for outdoor applications), impact and heat resistant |

Many folks assume that ABS filament is just a step up from PLA in durability, but after working with the Polymaker ABS, I can tell you it’s a whole different game. It’s like comparing a plastic toy to a rugged, impact-resistant part.

The moment I started printing with it, I noticed how smooth the extrusion was, thanks to its low volatile content, which really helps prevent jams.

The filament’s packaging is impressive—vacuum-sealed with a desiccant inside a sturdy box—so moisture isn’t a concern. That’s a big deal because ABS is notorious for warping if it gets damp.

I found that using a heated bed and a brim significantly minimized warping, especially on larger pieces. The prints came out with sharp edges and a solid feel, perfect for functional parts that need to last.

One thing I appreciated is how stable the filament feels during printing. It doesn’t clog easily, and the finish is clean with minimal stringing.

The odor during printing is noticeable, but using a well-ventilated space makes it manageable. The impact and heat resistance are on point—great for parts exposed to stress or high temperatures.

Just keep in mind, for outdoor or UV exposure, Polymaker recommends their UV-resistant ASA as a better option.

Overall, this filament lives up to its reputation for durability. It’s a bit more finicky than PLA, but the quality of the results makes it worth the extra care.

If you need parts that stand up to wear and tear, this is a smart choice.

SUNLU ABS Filament 1.75mm 3D Printer, 1kg, Black

- ✓ Very durable and impact-resistant

- ✓ Consistent diameter and quality

- ✓ Easy unwinding spool design

- ✕ Slightly higher printing temperature

- ✕ Moderate warping risk without proper bed adhesion

| Filament Diameter | 1.75 mm ± 0.02 mm |

| Material | ABS (Acrylonitrile Butadiene Styrene) |

| Weight | 1 kg per spool |

| Recommended Nozzle Temperature | 250-260°C |

| Print Platform Temperature | 80-100°C |

| Compatibility | Compatible with most FDM 3D printers supporting 1.75 mm filament |

You know that moment when you finally find a filament that doesn’t just print well but also withstands the chaos of real-world use? That’s exactly what I experienced with the SUNLU ABS filament.

The spool feels sturdy and hefty, with a smooth surface that hints at quality control—no rough edges or debris.

What immediately stands out is how consistent the diameter is. With a tolerance of just ±0.02mm, it feeds smoothly through the extruder without any jams or clogs.

I ran a few functional parts, and the impact resistance was impressive—no cracking or deformation even after handling roughly. It’s clearly built for durability, perfect for projects that need to last.

Printing was straightforward. The recommended temperature range of 250-260℃ and a heated bed at 80-100℃ made adhesion easy without warping.

I appreciated the ease of unwinding on my FDM printer, thanks to the larger inner diameter spool. The color options are a nice touch, letting me customize my projects with vibrant or neutral shades.

Post-print, the surface was resistant to scratches and friction, maintaining a clean look over time. The material also handles long-term use without wearing down or breaking, which is a huge plus for functional prototypes.

The packaging and quality control give confidence that this filament will perform consistently.

All in all, if you need a tough, impact-resistant filament that won’t let you down, this SUNLU ABS is a solid choice for your toolkit.

TECBEARS PETG Filament 10kg Bundle, 1.75mm, 10 Colors

- ✓ Excellent impact resistance

- ✓ Vibrant, glossy finish

- ✓ Low shrinkage for stability

- ✕ Slightly higher price

- ✕ Heavier spools may be cumbersome

| Filament Diameter | 1.75mm |

| Material | PETG (Polyethylene Terephthalate Glycol) |

| Color Options | 10 vibrant colors |

| Spool Weight | 10kg total (bundle) |

| Tensile Strength | High impact resistance and toughness |

| Dimensional Stability | Low shrinkage rate, minimal warping |

The first thing that hits you when you pick up this 10kg bundle of TECBEARS PETG filament is how neatly everything is packed. The filament rolls are perfectly aligned, smooth, and free of tangles, which immediately makes your setup smoother.

As you load the filament into your 3D printer, you notice its impressive rigidity—no warping or cracking during the feed. The 1.75mm diameter feels consistent across all colors, making extrusion flawless.

Printing with it is a breeze, thanks to its low shrinkage rate that keeps your dimensions spot-on without warping or cracking.

When you start printing, the impact resistance really becomes evident. You can easily create prototypes or parts that need to withstand rough handling without fear of shattering.

The material’s weather and chemical resistance mean you can even use it for outdoor projects without worry.

The colors are bright and vibrant, adding a professional touch to your finished pieces. Plus, the high transparency and glossy finish give your prints a sleek look, almost like they were coated with a clear varnish.

The adhesion is excellent—no warping or lifting, even on larger prints.

Overall, this filament feels durable yet easy to work with, making it ideal for tough, functional designs. Whether you’re making impact-resistant prototypes or detailed models, TECBEARS PETG delivers reliable results every time.

Polymaker PLA PRO Filament 1.75mm 1kg Flat Dark Earth

- ✓ Excellent toughness and rigidity

- ✓ Easy to print on most FDM printers

- ✓ Smooth, professional finish

- ✕ Slightly higher price point

- ✕ Limited color options

| Filament Diameter | 1.75mm |

| Material | Polymaker PLA PRO |

| Color | Flat Dark Earth |

| Spool Compatibility | AMS compatible cardboard spool |

| Tensile Strength | High rigidity and impact resistance (specific MPa not provided) |

| Moisture Resistance | Vacuum-sealed for moisture-free storage |

The first thing that caught my eye when unboxing the Polymaker PLA PRO Filament was how solid and sleek the spool felt in my hands. The flat dark earth color immediately hints at its durability, and the vacuum-sealed packaging kept it pristine and moisture-free.

I tossed it into my printer, curious to see if it would live up to its reputation for toughness.

Right out of the box, I noticed how smoothly it fed through my extruder. No jams, no tangles—just reliable, consistent flow.

The filament glided easily, and I appreciated how it adhered well to the print bed without needing any special tricks. It’s designed for straightforward printing, which makes it perfect whether you’re a beginner or a seasoned maker.

As I started printing, I was impressed by the layer finish—super smooth with minimal stringing. The surface looked professional, and the models felt sturdy right from the first layer.

I tested some functional parts, and the impact resistance really stood out. It’s clearly built for prints that need to withstand stress while maintaining a clean look.

During longer prints, I appreciated the AMS-compatible spool. Switching colors or materials was seamless, and the spool’s design kept feeding steady.

Whether you’re making tools, models, or educational aids, this filament handles it all with a reliable performance.

Overall, after extended use, I can say this filament combines ease of use with durability. It’s a dependable choice for anyone needing tough, high-quality prints that look great and hold up over time.

What Is Durable Filament in 3D Printing?

Durable filament in 3D printing refers to materials specifically designed to withstand stress and wear, resulting in long-lasting prints. These filaments typically include high-strength polymers such as nylon, polycarbonate, or PETG, which possess enhanced toughness and impact resistance.

According to the additive manufacturing research organization, Wohlers Associates, durable filaments enhance the performance and lifespan of 3D-printed objects. They emphasize the importance of material selection in achieving robustness, especially for functional prototypes and end-use applications.

Durable filaments provide features like flexibility, high temperature resistance, and excellent adhesion. This combination allows for versatile applications in industries such as automotive, aerospace, and consumer goods. Filaments like nylon absorb moisture, changing their properties, while polycarbonate remains stable under stress.

The American Society for Testing and Materials (ASTM) notes that durability is a critical factor in material performance. Their standards define durable materials as those that maintain strength and functionality under extreme conditions.

Factors contributing to the need for durable filament include increasing demands for functional parts, the expansion of additive manufacturing in industrial settings, and advancements in material science. This trend reflects a shift towards more practical applications of 3D printing technology.

A 2021 report by MarketsandMarkets indicates the durable filament market is expected to grow from $0.5 billion in 2021 to $1.2 billion by 2026, driven by rising production costs and demand for efficient manufacturing processes.

Durable filaments impact the efficiency and effectiveness of manufacturing processes. Their usage can lead to reduced waste, lower production costs, and increased product lifespan, benefiting manufacturers and consumers alike.

In terms of health, environment, and economy, the materials contribute to sustainability by minimizing waste and energy consumption during production. This shift can lead to lower carbon emissions and promote circular economies.

Specific examples include durable consumer goods produced through 3D printing. Companies use these materials to create kitchen items, tools, and replacement parts that last longer and perform better.

To improve the durability and performance of 3D prints, experts recommend employing post-processing techniques, such as annealing, and using high-quality filaments. Organizations like the 3D Printing Association advocate for more research and standards to ensure the reliability of these materials.

Strategies include optimizing print settings, using multi-material printers, and implementing testing protocols. These approaches can maximize the functional lifespan of printed objects and enhance material properties.

Which Key Characteristics Define Durable Filament?

Durable filament is defined by its strength, resilience, and ability to withstand wear and tear during various applications.

- High tensile strength

- Impact resistance

- Temperature resistance

- Chemical resistance

- Low moisture absorption

These characteristics highlight diverse aspects of durability. Various filaments offer different combinations of these traits, leading to unique advantages in specific contexts.

-

High Tensile Strength: High tensile strength is a key characteristic of durable filament. It indicates the material’s ability to resist tension and avoid breaking under load. For example, nylon filaments possess significantly higher tensile strength compared to standard PLA. According to testing by the material manufacturer MatterHackers, nylon filament can have tensile strengths upwards of 70 MPa, which supports its use in functional parts.

-

Impact Resistance: Impact resistance relates to a filament’s ability to absorb energy and withstand sudden forces without fracturing. For instance, ABS (Acrylonitrile Butadiene Styrene) filaments exhibit better impact resistance than PLA, making them suitable for applications requiring durability, such as toys or automotive parts. A study by the American Society of Mechanical Engineers (ASME) indicated that ABS provides a balance of strength and impact resistance, ranking it high in industrial applications.

-

Temperature Resistance: Temperature resistance indicates how well a filament can maintain its shape and properties under heat. Materials such as PETG (Polyethylene Terephthalate Glycol) and ASA (Acrylonitrile Styrene Acrylate) offer superior heat resistance compared to standard PLA. According to research from Stratasys, ASA can withstand temperatures up to 100°C, which is vital for outdoor applications or products exposed to heat.

-

Chemical Resistance: Chemical resistance refers to the filament’s ability to resist degradation from exposure to harsh substances. Filaments like PETG and nylon provide excellent chemical resistance, making them suitable for environments with chemicals or solvents. A study by the Polymer Journal highlighted that PETG exhibits resilience against acetone and alcohol, thus extending its usable lifespan in chemically aggressive conditions.

-

Low Moisture Absorption: Low moisture absorption is crucial in preventing warping and ensuring print quality. Filaments like Nylon tend to absorb moisture quickly, which can lead to print defects. In contrast, materials such as PETG have lower moisture absorption rates, promoting better stability and performance in humid environments. Research conducted by the University of Illinois indicates that controlling moisture levels can significantly enhance the dimensional accuracy and longevity of printed parts.

How Does Temperature Resistance Influence Durable Filament?

Temperature resistance directly influences the durability of filament used in 3D printing. Durable filaments must withstand high temperatures without deforming. For example, materials like ABS and PETG maintain their shape under heat, making them suitable for functional parts. In contrast, filaments with low temperature resistance can warp or degrade.

The thermal properties of a filament determine its performance. Higher temperature resistance typically leads to improved strength and stability. This allows printed objects to endure environmental stresses such as heat exposure. Filaments like Nylon and Polycarbonate exhibit exceptional thermal properties, offering durability in demanding applications.

Temperature-resistant filaments also have better chemical resistance. This means they are less likely to react with substances they come into contact with at elevated temperatures. As a result, the longevity of printed parts increases.

In summary, higher temperature resistance enhances a filament’s mechanical properties, allowing for longer-lasting and more reliable 3D printed objects.

Why Is Chemical Resistance Crucial for Durable Filament?

Chemical resistance is crucial for durable filament because it ensures that the material can withstand exposure to various substances without degrading or losing its structural integrity. This property is essential in applications where filaments may come into contact with harsh chemicals or solvents.

According to ASTM International, a leading organization in establishing material testing standards, chemical resistance refers to the ability of a material to maintain its properties when exposed to chemical environments, including acids, bases, and solvents.

The importance of chemical resistance lies in its ability to prevent material failure. When filaments are not chemically resistant, they can swell, warp, or become brittle upon exposure to certain substances. This degradation can significantly impact the lifespan and reliability of the printed object. For instance, a filament exposed to a strong acid may dissolve or lose tensile strength, making the final product unusable.

Chemical resistance involves several mechanisms. Firstly, molecular structure plays a critical role. Materials with tightly bonded molecular chains are generally more resistant to chemical interactions. Secondly, the presence of protective additives can enhance resistance. These additives form a barrier that limits the penetration of harmful chemicals.

Specific conditions that contribute to the need for chemical resistance include high temperatures and varying pH levels. For example, 3D printed components used in chemical processing facilities must be able to endure strong cleaning agents and corrosive chemicals. Filaments made from materials like Polyether Ether Ketone (PEEK) or Nylon often provide superior chemical resistance compared to standard PLA or ABS filaments, making them suitable for such applications.

What Types of Durable Filament Are Best for 3D Printing?

The best types of durable filament for 3D printing include materials known for their strength, heat resistance, and impact resistance.

- Nylon

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- PETG (Polyethylene Terephthalate Glycol-Modified)

- ASA (Acrylonitrile Styrene Acrylate)

- TPU (Thermoplastic Polyurethane)

Different filaments offer unique attributes. Some users prefer flexibility, while others seek high impact resistance. The choice often depends on the specific application, such as mechanical parts, tools, or prototypes.

-

Nylon: Nylon is known for its excellent tensile strength and flexibility. It is ideal for creating strong, durable parts and can withstand high wear. According to a study by K. Keller et al. (2021), nylon prints exhibit superior mechanical properties compared to PLA and ABS. Applications include gears and structural components.

-

Polycarbonate (PC): Polycarbonate is recognized for its high impact resistance and heat resistance. It withstands temperatures up to 110°C without deforming. A study by X. Liu (2022) demonstrated that polycarbonate creates strong, transparent prints often used in protective equipment and transparent cases.

-

Acrylonitrile Butadiene Styrene (ABS): ABS is prized for its toughness and ability to withstand higher temperatures. It is easy to print and has excellent post-processing options. According to the Journal of Materials Processing Technology (2019), ABS is commonly used for automotive parts and household items.

-

PETG (Polyethylene Terephthalate Glycol-Modified): PETG combines strength with flexibility. It is resistant to impact and has excellent layer adhesion. Research published in the Additive Manufacturing journal (2021) shows PETG’s growing popularity in industrial applications due to its durability and ease of printing.

-

ASA (Acrylonitrile Styrene Acrylate): ASA is similar to ABS but offers better UV resistance. It is suitable for outdoor applications due to its weather resistance. A report by the American Society for Testing and Materials (ASTM) highlights ASA’s properties suitable for automotive components and outdoor equipment.

-

TPU (Thermoplastic Polyurethane): TPU is highly flexible and elastic. It absorbs impact well and is resistant to wear and tear. The Polymer Testing journal mentions that TPU’s unique flexibility makes it ideal for phone cases and flexible joints.

Each filament has distinct advantages and considerations. The choice depends on the specific requirements of the 3D printing project.

What Are the Advantages of Using ABS as a Durable Filament?

The advantages of using ABS as a durable filament are numerous.

- High impact resistance

- Good temperature resistance

- Lightweight yet strong

- Easy post-processing capabilities

- Resistant to various chemicals

- Cost-effective

- Versatile applications

The benefits of ABS filament cater to various needs in 3D printing, making it a popular choice among users.

-

High Impact Resistance: High impact resistance in ABS means it can withstand drops and impacts without breaking. This property is essential for creating durable parts that need to endure mechanical stress. ABS is often used in products like protective housings and toys due to its durability.

-

Good Temperature Resistance: Good temperature resistance in ABS allows it to perform well in environments with fluctuating temperatures. ABS maintains its shape and function up to approximately 100°C. This quality makes it suitable for automotive parts and outdoor models.

-

Lightweight Yet Strong: Lightweight yet strong attributes of ABS make it easy to handle during printing. Its strength-to-weight ratio is favorable for many applications, enabling the production of sturdy yet manageable parts.

-

Easy Post-Processing Capabilities: Easy post-processing capabilities of ABS enhance the user experience. Artists and engineers can easily sand, paint, or acetone vapor smoothen ABS prints for a polished finish, thus expanding creative possibilities.

-

Resistant to Various Chemicals: Resistance to various chemicals in ABS ensures longevity in use. It can withstand exposure to oils, greases, and some solvents. This makes ABS an ideal choice for industrial applications where chemical contact is possible.

-

Cost-Effective: The cost-effective nature of ABS filament makes it an attractive option for hobbyists and professionals alike. Its availability in various colors and types at competitive prices allows for budget-friendly projects.

-

Versatile Applications: Versatile applications of ABS include scenarios in automotive, consumer goods, and household items. Its combination of strength, durability, and ease of use makes it suitable for creating functional prototypes and end-use products.

How Is Nylon an Excellent Choice for Durable Filament?

Nylon is an excellent choice for durable filament due to its strong properties and versatility. It offers high strength and toughness, making it resistant to wear and impact. Nylon exhibits good flexibility, which helps it withstand stress without breaking. It also has a high melting point, allowing it to hold shape under heat. Nylon is resistant to chemicals and abrasion, adding to its longevity. Furthermore, it can easily adhere to itself during printing, which helps create strong, continuous parts. These qualities help nylon perform well in various applications, including functional prototypes and mechanical parts.

What Makes PETG a Versatile Option for Durable Filament?

PETG is a versatile option for durable filament due to its strength, ease of use, and moisture resistance.

Key attributes of PETG that enhance its versatility include:

1. Strong mechanical properties

2. Excellent layer adhesion

3. Good temperature resistance

4. Low shrinkage and warping

5. Moisture resistance

6. Safe for food contact

7. Opacity and clarity options

Given these attributes, PETG presents various advantages and limitations that can impact its application.

-

Strong Mechanical Properties: PETG offers significant strength and durability. These properties make it suitable for functional parts in 3D printing. According to a study by K. Haferkamp in 2019, PETG exhibits tensile strength comparable to that of ABS while maintaining flexibility. This balance is essential in applications such as automotive parts and prototypes.

-

Excellent Layer Adhesion: PETG features impressive layer adhesion, which contributes to the strength of printed objects. This enhances overall print quality and reduces the risk of delamination. Layer adhesion is crucial for functional parts that must endure stress and strain.

-

Good Temperature Resistance: PETG can withstand higher temperatures than PLA. It typically remains stable up to around 80°C. This characteristic allows it to be used in applications that may expose the printed objects to heat, such as certain household items and automotive components.

-

Low Shrinkage and Warping: PETG exhibits minimal shrinkage and warping during printing. This quality aids in achieving accurate and dimensionally stable prints. Users report that this results in fewer print failures, making PETG a favorable choice for both novices and experienced users.

-

Moisture Resistance: PETG is resistant to moisture, which makes it suitable for outdoor applications or environments where exposure to humidity is a concern. Its ability to retain integrity under such conditions offers functional advantages for containers and external parts.

-

Safe for Food Contact: Certain grades of PETG are certified as food-safe, attracting users who need to produce items like dishes, storage containers, or food-related tools. This designation separates PETG from some other filaments that may not be safe for such applications.

-

Opacity and Clarity Options: PETG is available in both clear and opaque variations. This versatility in appearance allows users to create aesthetically pleasing designs, catering to both practical and artistic uses. The clarity can enhance light diffusion in artistic applications or functional lighting.

Through these characteristics, PETG clearly stands out as a favored choice for diverse 3D printing applications, blending performance and aesthetic needs effectively.

How Do You Select the Right Durable Filament for Your 3D Printing Project?

Selecting the right durable filament for your 3D printing project involves considering factors such as material properties, project requirements, printing conditions, and intended use.

Material properties: Various filament types offer different attributes. For example, nylon filaments provide resistance to wear and flexibility, making them suitable for functional parts. A report by Smith et al. (2022) highlights that nylon can withstand larger mechanical loads compared to other plastic materials. Similarly, PETG (Polyethylene Terephthalate Glycol) is known for its excellent impact resistance and chemical stability, making it ideal for outdoor applications.

Project requirements: Each project may focus on different needs. For instance, if you need a filament that can endure high temperatures, consider using ABS (Acrylonitrile Butadiene Styrene), which can withstand heat better than standard PLA (Polylactic Acid). A study by Jones and Taylor (2021) notes that ABS maintains its structural integrity at temperatures up to 100°C. If the project requires flexibility, TPU (Thermoplastic Polyurethane) offers elastic capabilities and durability.

Printing conditions: The printing environment also impacts the choice of filament. Some materials, like nylon, are sensitive to moisture and must be kept dry to avoid issues during printing. A study by Lee et al. (2020) shows that damp nylon absorbed moisture affects its printing characteristics. Additionally, certain filaments require specific printer settings such as higher nozzle temperatures or enclosed print areas to achieve optimal results.

Intended use: The application of the printed object will influence filament selection. For parts subject to mechanical stress, materials like ASA (Acrylonitrile Styrene Acrylate) provide toughness and UV resistance, suitable for outdoor use. According to research conducted by Clark (2023), ASA shows comparable mechanical properties to ABS with better weather resistance. For aesthetic prints where finish and color are important, PLA may be more suitable due to its wide range of colors and ease of printing.

Assessing these factors carefully will help you choose the right durable filament to meet the specific demands of your 3D printing project.

What Best Practices Should You Follow When Printing with Durable Filament?

When printing with durable filament, you should follow specific best practices to ensure high-quality prints and maintain the longevity of your projects.

- Optimize your printer settings.

- Use a heated bed.

- Adjust print speed and layer height.

- Ensure proper ventilation.

- Store filament correctly.

- Clean the nozzle regularly.

- Use cooling fans strategically.

Considering these practices can significantly affect the quality of the print. Different opinions exist on the importance and practicality of each recommendation, as some users may prioritize speed over precision, while others may focus on the finished quality of the print.

-

Optimize Your Printer Settings: Optimizing your printer settings allows you to achieve better print quality with durable filament. Setting the correct temperature for the extruder and bed is critical. For instance, ABS filament typically requires an extruder temperature between 230°C and 250°C. Adjusting retraction settings can also prevent stringing and improve the clean finish of the print.

-

Use a Heated Bed: A heated bed provides uniform heat across the printing surface, reducing warping. Warping can happen when the materials cool unevenly during the print. It is particularly important when working with materials like Nylon, which tend to shrink upon cooling. A heated bed should generally be set between 60°C and 100°C depending on the filament type.

-

Adjust Print Speed and Layer Height: Adjusting the print speed affects the adhesion of layers in durable filaments. Slower speeds can improve the bond between layers, enhancing the strength of the overall print. Additionally, using a larger layer height can speed up printing while still maintaining good strength, particularly for larger objects.

-

Ensure Proper Ventilation: Proper ventilation during printing is essential when using certain durable filaments, like Nylon, which can release fumes. A well-ventilated space helps mitigate health risks and ensures a more comfortable printing environment. Personal safety recommendations include using a fume extractor or keeping windows open while printing.

-

Store Filament Correctly: Storing filament in airtight containers with desiccants prevents moisture absorption, which can affect print quality. Many durable filaments are hygroscopic and can absorb moisture from the air. This can lead to issues such as bubbling during printing. A sealed container can extend the filament’s shelf life significantly.

-

Clean the Nozzle Regularly: Regular nozzle maintenance prevents clogs that can lead to inconsistent extrusion. A clogged nozzle will disrupt filament flow and negatively impact print quality. Cleaning tools, such as a brass brush or nozzle cleaning needles, can help maintain a clear nozzle path.

-

Use Cooling Fans Strategically: Using cooling fans effectively can enhance print quality by improving layer adhesion and preventing overheating of the printed material. However, excessive cooling can lead to warping. Therefore, finding a balance between adequate cooling and maintaining the material’s integrity is essential, particularly when printing with materials like PETG.