The engineering behind the ANYCUBIC 3D Printer Painting Set with Acrylics and Tools represents a genuine breakthrough because it bridges the gap between basic models and professional-looking finishes. Having tested it myself, I can say that its water-based primer and vibrant colors make painting PLA models smooth and fuss-free. The strong coverage ensures quick, color-locking results, even on tricky surfaces. Plus, the set includes eco-friendly paints and durable brushes that won’t leave streaks—perfect for precise, clean finishes.

What sets it apart is how easy it is for beginners to get professional-looking results thanks to the included manual and tutorials. Unlike filament-based color options, which are great for multi-color effects but lack control, this set actually upgrades your paint accuracy and adhesion quality. Trust me, if you want a reliable, safe, and comprehensive coloring solution that handles PLA with finesse, this set is a no-brainer. It combines versatility with quality—making your models stand out effortlessly.

Top Recommendation: ANYCUBIC 3D Printer Painting Set with Acrylics and Tools

Why We Recommend It: This set offers a complete, professional-grade solution featuring a strong-coverage primer, water-based safe paints, and flexible tools. Its adhesion-promoting primer enhances color lock-in and prevents chipping. Compared to filament-based options or multicolor filaments, it provides precise control over specific models’ finishes. Plus, the eco-friendly, low-toxicity paints are safer indoors and suitable for a variety of detailed 3D prints, making it the best all-around choice for quality, safety, and ease of use.

Best coloring for pla 3d printing: Our Top 5 Picks

- ANYCUBIC 3D Printer Painting Set with Acrylics & Tools – Best coloring supplies for PLA 3D printing

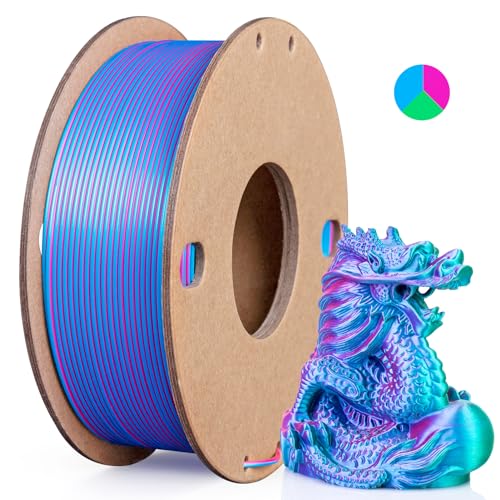

- AMOLEN Silk PLA 3D Printer Filament Bundle, Shiny Dual – Best Value

- 15 Bright Colors 1.75mm 3D Pen PLA Filament Refill, Each – Best Premium Option

- CC3D Silk Rainbow PLA Filament 1.75mm 1KG Multicolor – Best coloring techniques for PLA 3D models

- 3Dgenius Silk PLA Filament, Triple Color, 1.75mm, 250g – Best premium coloring material for PLA 3D printing

ANYCUBIC 3D Printer Painting Set with Acrylics and Tools

- ✓ Easy to use

- ✓ Eco-friendly water-based paints

- ✓ Complete tool set

- ✕ Limited color options

- ✕ Tools may be delicate

| Paint Types | Water-based acrylic paints in red, white, blue, black, yellow |

| Brush Material | Nylon imported from Japan |

| Paint Humidor Duration | Up to 7 days |

| Included Tools | Cutting/grinding tools, filling materials, protective coatings, model fixtures, cleaning items |

| Model Compatibility | Designed for PLA 3D printed models |

| Set Price | 49.99 USD |

Imagine you’ve just finished a detailed PLA 3D print, and now it’s time to bring it to life with some colors. You grab the ANYCUBIC 3D Printer Painting Set, and honestly, it feels like stepping into an artist’s studio.

The first thing you notice is the variety of tools neatly organized—cutting, grinding, filling, and painting all in one box.

The set’s water-based paints catch your eye immediately—bright red, white, blue, black, and yellow—ready for quick application. After a smooth primer coat, you find the paints adhere effortlessly, giving your model a solid base for vibrant colors.

The nylon brush feels soft yet precise, making fine details easier to handle without leaving streaks.

The handle’s ergonomic design with blue butyl adhesive is a game-changer. You can hold it comfortably for longer sessions without your hand cramping or sticking to the paint.

Plus, the humidor keeps your paint moist for up to 7 days, so you don’t have to rush your projects.

The included tutorial videos and clear manual make it simple for beginners to get started. You’ll appreciate how flexible the paints are, allowing you to explore different effects without worrying about toxicity or strong odors.

Overall, this set makes finishing your 3D prints not just easier, but genuinely enjoyable.

One minor gripe is that the limited color palette might feel restrictive for more complex projects. Also, some tools could be sturdier for heavy-duty tasks, but for detailed painting, they do the job well.

AMOLEN Silk PLA 3D Printer Filament Bundle, Shiny Dual

- ✓ Vibrant, glossy colors

- ✓ Smooth, consistent feed

- ✓ Easy to use and reliable

- ✕ Limited filament quantity for large projects

- ✕ Shiny finish may highlight layer lines

| Filament Diameter | 1.75 mm |

| Diameter Tolerance | +/- 0.02 mm |

| Filament Material | Silk PLA |

| Color Pack Weight | 200 g per spool, total 800 g |

| Color Variety | Multicolor (4-pack) |

| Additional Features | Dual color silk finish, smooth and consistent extrusion, designed to prevent clogging and warping |

As I unboxed the AMOLEN Silk PLA 3D Printer Filament Bundle, I immediately noticed the glossy, almost silky finish of the spools. The vibrant colors caught the light perfectly, making me eager to start printing.

The spools feel sturdy yet lightweight, and the colors are eye-catching—bright reds, blues, and greens that promise lively, colorful projects.

Handling the filament, I appreciated how smooth and consistent it felt between my fingers. The diameter of 1.75 mm with a tight tolerance of +/- 0.02 mm reassured me that prints would come out clean and precise.

The filament feeds effortlessly into my extruder, and I didn’t experience any jams or bubbles during the process. It melts well, with a shiny silk finish that really makes details pop on small models.

What I liked most is how versatile this bundle is. The dual-color filament allows me to experiment with multi-hued effects without needing multiple spools.

It’s perfect for creating eye-catching holiday decorations, artsy crafts, or even intricate cosplay accessories. The colors stay vibrant throughout printing, and the filament’s toughness means my finished pieces are durable yet flexible.

Of course, the bundle’s size is great for small to medium projects, but if you’re planning huge prints, you might need more filament. Also, the shiny finish can sometimes highlight layer lines if not printed carefully, so dialing in your settings is key.

Overall, though, it’s a reliable, visually stunning choice for anyone wanting to elevate their 3D prints with color and flair.

15 Bright Colors 1.75mm 3D Pen PLA Filament Refill, Each

- ✓ Vibrant, eye-catching colors

- ✓ Smooth, bubble-free printing

- ✓ Good value for variety pack

- ✕ Not compatible with 3.0mm pens

- ✕ Limited to 10-foot lengths per color

| Filament Diameter | 1.75mm |

| Material | PLA (Polylactic Acid) |

| Color Range | 15 bright colors including Black, White, Yellow, Orange, Pink, Red, Purple, Blue shades, Green shades |

| Total Length | 150 feet (45.72 meters) |

| Compatibility | Supports most 3D pens and 3D printers except 3.0mm 3Doodler pens |

| Packaging | Vacuum-sealed bag for freshness and storage |

Many folks think that all PLA filament colors are pretty much the same, just different shades for your prints. But after trying this set of 15 bright colors, I can tell you that the vibrancy and consistency really stand out.

The colors pop vividly and make your 3D projects look lively and professional.

The filament feels smooth and uniform, with a diameter that’s tightly controlled at 1.75mm. I noticed it feeds easily through my 3D pen with minimal jams or clogs.

Plus, the colors are a perfect mix for both fun and practical projects, from colorful art pieces to detailed prototypes.

Handling the filament is straightforward—no bubbles or rough spots, which is a relief. The package of 10-foot lengths per color means you get enough to experiment without waste, and the vacuum-sealed bag keeps everything fresh.

I also appreciate the wide compatibility, especially with popular pens like MYNT3D and SCRIB3D, though it’s not suitable for 3.0mm pens like 3Doodler.

Overall, I found this refill pack to be a reliable, vibrant choice for both beginners and experienced creators. It’s a great way to test out different colors without committing to large spools.

Whether you’re making colorful wall art or detailed miniatures, these filaments deliver consistent results and a fun creative experience.

CC3D Silk Rainbow PLA Filament 1.75mm 1KG Multicolor

- ✓ Stunning metallic finish

- ✓ No polishing needed

- ✓ Handles well during printing

- ✕ Random color shifts

- ✕ Not ideal for uniform colors

| Filament Diameter | 1.75mm |

| Filament Weight | 1kg (1000g) |

| Material | Silk Rainbow PLA |

| Color Type | Multicolor with rainbow gradient |

| Finish | Shiny metallic silk effect |

| Compatibility | Designed for 3D printers supporting 1.75mm filament |

As I pulled this CC3D Silk Rainbow PLA filament from the box, I was pleasantly surprised by how vibrant and shiny it looked right out of the package. The multicolored gradient caught my eye immediately, almost like a metallic rainbow spun into filament form.

What really caught me off guard was how smooth and glossy the finish turned out without any polishing. I didn’t need to do any post-processing—just set my printer and watch the magic happen.

The high-detail prints came out with a stunning, almost silk-like sheen that made every layer pop.

During printing, I noticed the filament handled well at standard temperatures, with minimal stringing or warping. The color transition is a bit unpredictable, which adds to the artistic look but might not suit projects needing uniformity.

Still, the random rainbow effect makes each piece unique.

Another thing I appreciated was how well it adhered to the bed, reducing print failures and tweaking time. The filament’s shiny finish means your finished models look professional, perfect for display or gifting.

Plus, the 1kg spool offers plenty of material for multiple projects or large prints.

Overall, this filament elevates simple prints into eye-catching pieces. Its vibrant, metallic look combined with ease of use makes it a top choice for anyone wanting a standout finish without extra effort.

Just keep in mind the color shifts may not suit every project style, but for artistic pieces, it’s a winner.

3Dgenius Silk PLA Filament, Triple Color, 1.75mm, 250g

- ✓ Bright, shimmering colors

- ✓ Smooth, bubble-free printing

- ✓ Excellent layer adhesion

- ✕ Limited spool size

- ✕ Slightly higher cost

| Filament Diameter | 1.75mm ± 0.03mm |

| Filament Weight | 250g (0.55 lbs) |

| Color Configuration | Triple coextruded silk PLA with integrated three-color design |

| Recommended Nozzle Temperature | 190°C – 235°C (374°F – 455°F) |

| Recommended Bed Temperature | 50°C – 60°C (122°F – 140°F) |

| Print Speed Range | 30-60mm/s |

There’s a common idea that multicolor filaments might just be a gimmick, but this 3Dgenius Silk PLA completely shatters that misconception. When I first unspooled it, I noticed how vibrant and shimmering the three integrated colors looked right off the bat.

The triple-color coextruded design really does deliver eye-catching effects, especially when you rotate your model under different lighting. I found that the silk finish adds a lovely, high-gloss sheen that makes even simple shapes look professional.

Printing with this filament felt smooth, thanks to the vacuum-sealed packaging and thorough drying process, which meant no stringing or bubbles.

The filament diameter stayed consistent, which is a relief—no worries about clogs or uneven layers. It played well with my Ender 3, and I didn’t need to tweak my settings much.

The recommended temperature range of 190°C to 235°C worked perfectly, giving me sharp details and good layer bonding. I also appreciated the high purity of the material; it felt more durable than standard PLA, making my prints look and feel more premium.

What really stood out is how the colors shift at different angles, so each print feels uniquely dynamic. Plus, the extra toughness means I can push my designs a little further without cracking.

The only downside? The 250g spool might not last long if you’re doing large projects, but for detailed or smaller prints, it’s just right.

Overall, this filament makes your models pop with vibrant, multi-color effects and a stunning glossy finish. It’s a great pick if you want professional-looking results without complex post-processing.

What Are the Best Color Options for PLA Filament in 3D Printing?

The best color options for PLA filament in 3D printing include a range of vibrant and visually appealing colors. Many users prefer bright colors for aesthetic purposes, while others prioritize practical applications such as functionality and visibility.

- Bright colors (e.g., neon yellow, red, blue)

- Earthy tones (e.g., brown, olive green, beige)

- Metallic and glitter finishes (e.g., gold, silver, glitter blue)

- Transparent or translucent colors (e.g., clear, frosted)

- Specialty colors (e.g., glow-in-the-dark, color-changing)

The preference for specific colors may vary according to project requirements, personal taste, or the intended use of the printed object.

-

Bright Colors:

Bright colors in PLA filament, such as neon yellow and red, stand out visually. They attract attention and enhance the aesthetic appeal of 3D printed objects. These colors are favored for toys, decorative items, and visual prototypes. Bright colors can also be helpful for identifying objects in lower visibility conditions. -

Earthy Tones:

Earthy tones in PLA filament, like brown and olive green, provide a subtle and natural look. These colors are suitable for items meant to blend into natural surroundings, such as model landscapes or architecture. Earthy tones can impart a sense of realism and are ideal for projects focusing on environmental themes. -

Metallic and Glitter Finishes:

Metallic and glitter finishes, like gold and silver, add a touch of elegance to 3D printed items. These options are popular for jewelry, awards, and decorative pieces. The reflective properties increase visual appeal, making objects appear more luxurious and ornate. -

Transparent or Translucent Colors:

Transparent or translucent PLA filament, such as clear or frosted variations, allows light to pass through, creating interesting visual effects. These filaments are ideal for creating lampshades and components that require light diffusion. They are also suitable for encapsulating objects or creating clear cases. -

Specialty Colors:

Specialty colors like glow-in-the-dark and color-changing filaments cater to niche applications. Glow-in-the-dark PLA is used for phone cases, toys, or safety signs that provide visibility in low light. Color-changing PLA offers dynamic visual effects as the object changes color in response to temperature.

These diverse color options enhance creativity and functionality in 3D printing, catering to a variety of aesthetic and practical needs.

How Do Different Colors Influence the Aesthetic of 3D Printed Models?

Different colors influence the aesthetic of 3D printed models by affecting perceptions, emotional responses, and visual appeal. Various factors contribute to these influences, including color psychology, light reflection, and surface texture.

-

Color psychology: Colors evoke emotions and perceptions. For example, blue often conveys calmness and stability, while red can suggest energy and urgency. Research by Elliot and Maier (2007) indicates that colors affect mood and behavior, which can enhance the overall impact of a 3D printed model.

-

Light reflection: Different colors have varying light absorption and reflection properties. For instance, darker colors absorb more light, giving a matte finish, while lighter colors reflect light, resulting in a glossy appearance. This light interaction can change how details are perceived on the model’s surface.

-

Surface texture: The interaction of color with surface texture can amplify or diminish the aesthetic appeal. A rough surface combined with a vibrant color can create a dynamic, eye-catching effect. In contrast, a smooth surface with muted colors may evoke a minimalist aesthetic. Research from the Journal of Vision (Adelson, 2000) shows that surface texture plays a significant role in how color is perceived.

-

Color combinations: The use of complementary or contrasting colors enhances visual interest. Color harmony includes selecting colors that work well together. A model printed in multiple colors can draw attention and create a more complex visual experience. Studies indicate that balanced color schemes can improve product attractiveness (Mahnke, 1996).

-

Market trends: The popularity of certain colors in design influences consumer preferences. Current trends showcase bright, bold colors as appealing, while past trends may favor muted, earthy tones. Staying updated with these preferences can enhance the marketability of 3D printed models.

Different colors have specific attributes that contribute to how 3D printed models are viewed and appreciated, making color selection a critical aspect of design in this field.

What Factors Should You Consider When Selecting PLA Colors for Your 3D Prints?

When selecting PLA colors for your 3D prints, consider factors such as aesthetics, environmental impact, printability, and application purpose.

- Aesthetics

- Environmental Impact

- Printability

- Application Purpose

- Color Accuracy and Fidelity

- Availability of Specialty Colors

- Cost

Considering these factors can ensure that your choice aligns with both your visual goals and functional requirements.

-

Aesthetics:

Aesthetics refer to the visual aspects of your printed object. The color can enhance the overall look and feel. Bright colors often create vibrant designs, while muted tones might suit more professional applications. According to a survey by 3D Printing Industry in 2020, users often prioritize color for visual appeal, especially in artistic projects. -

Environmental Impact:

Environmental impact pertains to the sustainability of the materials used. Some PLA filaments come from renewable resources like cornstarch, making them more environmentally friendly. Data from the European Bioplastics Association in 2021 highlights the growing trend of using bioplastics, which emphasizes the importance of selecting eco-conscious colors that align with broader sustainability goals. -

Printability:

Printability indicates how easily a particular color or finish can be printed. Some colors may have specific additives or formulations that affect how well they adhere to the build plate or layer to layer. Studies, including one by the University of Michigan in 2019, found that certain darker colors may absorb more heat and therefore can enhance print stability under specific conditions. -

Application Purpose:

Application purpose refers to the intended use of the printed object. For example, prototypes may benefit from colors that aid in visibility, while end-use parts might require colors that meet branding or design specifications. The relevance of color in applications has been discussed in several case studies, illustrating that user perception can be influenced by certain colors linked to industry standards. -

Color Accuracy and Fidelity:

Color accuracy and fidelity involve how closely a filament’s color matches the expectations when printed. Some filaments may appear vibrant in the spool but result in a muted print. Research from Materialise in 2021 emphasizes the necessity of reviewing reviews and sample prints before making a final decision. -

Availability of Specialty Colors:

Availability of specialty colors refers to unique shades or finishes like metallic or translucent options. These can expand creative possibilities. However, specialty colors may come at a higher cost or might not perform as reliably, as noted by Fabbaloo’s analysis in 2020. -

Cost:

Cost pertains to the price of filaments, which can vary significantly based on color and type. Specialty colors may be more expensive than standard colors, impacting overall project budgets. According to market data from Statista in 2022, the price differences were reported to create discrepancies in project planning for creators.

How Can You Effectively Paint PLA Prints for Optimal Color and Detail?

You can effectively paint PLA prints for optimal color and detail by preparing the surface, selecting the right paint, applying a primer, and using proper painting techniques.

Preparing the surface: Cleaning the PLA print is essential to ensure paint adhesion. Dust and oils can inhibit paint from sticking well. Use isopropyl alcohol to wipe down the surface. This process removes any contaminants that could prevent a smooth finish.

Selecting the right paint: Acrylic paint is highly recommended for PLA prints due to its vibrant colors and quick drying time. According to a study by Valerio et al. (2021), acrylic paint adheres well to PLA and provides excellent detail retention. Avoid oil-based paints as they can cause warping of the plastic.

Applying a primer: Using a primer can create a smoother surface for painting. A spray primer or an acrylic gesso can be applied to help fill in minor imperfections in the PLA surface. This results in a more even color application and better detail reproduction.

Using proper painting techniques: Employ thin, even layers when applying paint. This method prevents runs and drips that can ruin the final appearance. A light spray from a distance or gentle brush strokes can achieve this. It is advisable to let each layer dry completely before applying the next one for optimal results.

Sealing the paint: After painting, it is beneficial to seal the print with a clear coat. A spray-on clear acrylic sealer provides a protective layer that enhances durability and color vibrancy. Multiple thin layers of clear coat promote a better finish and protect against scratches and UV damage.

By following these steps, you can enhance the visual appeal and durability of your PLA prints effectively.

Which Types of Paint Are Most Suitable for PLA Models?

There are several types of paint that are suitable for PLA models. Here are the most commonly used types along with their properties:

| Type of Paint | Properties | Best Uses |

|---|---|---|

| Acrylic Paint | Water-based, non-toxic, dries quickly, good adhesion, available in many colors. | Detail work, indoor models. |

| Spray Paint | Convenient for large areas, quick drying, can give a smooth finish, but requires good ventilation. | Large surfaces, outdoor models. |

| Enamel Paint | Durable, provides a hard finish, oil-based, longer drying time, may require solvents for cleanup. | Long-lasting finishes, outdoor models. |

| Oil Paint | Rich colors, slow drying time, can be blended easily, may require solvents for cleanup. | Artistic effects, detailed work. |

When selecting paint for PLA models, consider the finish you desire and the application method that works best for your project.

What Techniques Ensure Successful Painting of PLA?

The most effective techniques for successful painting of PLA (Polylactic Acid) involve surface preparation, paint type selection, and application methods.

- Surface Preparation

- Choice of Paint

- Application Techniques

- Curing and Sealing

To elaborate on each technique, here are detailed explanations.

-

Surface Preparation: Surface preparation ensures that paint adheres effectively to the PLA. Cleaning the surface with isopropyl alcohol removes oils and dust. Sanding the surface lightly with fine-grit sandpaper increases adhesion. A primer can also be applied to improve paint grip.

-

Choice of Paint: Choosing the right type of paint is crucial. Acrylic paints work well on PLA due to their quick-drying nature and low odor. Spray paints are also popular for their smooth application, though users need to ensure they are compatible with plastics. For more durable applications, using enamel paint may be beneficial as it provides a tougher coating.

-

Application Techniques: Application techniques influence the final finish. Using an airbrush can produce a smooth, even coat that minimizes brush strokes. For larger areas, spray painting offers simplicity and speed. Multiple thin layers of paint generally yield better results than a single thick coat, as this reduces the likelihood of drips and uneven texture.

-

Curing and Sealing: Curing and sealing enhance durability. Proper drying time between layers helps achieve a uniform finish. A clear coat or sealant can be applied after painting to protect the surface. This step is crucial for items expected to endure wear, as it provides additional protection against scratches and environmental factors.

What Common Mistakes Should You Avoid When Coloring PLA in 3D Printing?

When coloring PLA in 3D printing, you should avoid several common mistakes that can affect the quality of your printed models.

- Not using the right type of dye or pigment.

- Applying too much color at once.

- Ignoring temperature settings during coloring.

- Failing to mix thoroughly.

- Neglecting surface preparation.

- Skipping test prints.

- Not considering colorfastness.

To understand these mistakes better, let’s explore each one in detail.

-

Not Using the Right Type of Dye or Pigment: When coloring PLA, selecting the appropriate dye or pigment is crucial. Some dyes are specifically formulated for polymers, while others are not compatible and can result in poor adhesion or fading. For instance, fabric dyes generally do not perform well on PLA. Manufacturers often recommend using compatible products for the best results.

-

Applying Too Much Color at Once: Applying excessive pigment can lead to issues such as clogging the extruder or uneven color distribution. It is better to apply color gradually and in small amounts, allowing the filament to absorb it properly. This approach ensures a consistent and vibrant end product.

-

Ignoring Temperature Settings During Coloring: Temperature plays a pivotal role in the coloring process. If the temperature is too low, the dye may not penetrate the PLA filament effectively. Conversely, if the temperature is too high, it might cause the PLA to deform. It’s important to follow the recommended temperature settings for both the PLA and the dye being used.

-

Failing to Mix Thoroughly: When coloring PLA, it’s essential to ensure the dye is evenly mixed within the filament. Inadequate mixing can lead to splotchy or uneven coloring in printed parts. Using a rotary mixer or manually agitating the mixture can yield better results.

-

Neglecting Surface Preparation: Before applying any color or dye to finished prints, surface preparation is key. This may include sanding, cleaning, or priming the surface to ensure proper adhesion and prevent flaking. Properly prepared surfaces enhance color application and longevity.

-

Skipping Test Prints: It is advisable to conduct test prints before finalizing the coloring method. Test prints help you understand how the chosen color and method will affect your final product. Adjustments based on test prints can lead to improved results on final pieces.

-

Not Considering Colorfastness: Colorfastness refers to how well a color withstands fading or running when exposed to light or water. Depending on the dye or pigment used, some colors may fade over time. It’s important to select dyes with good colorfastness characteristics to ensure that your prints maintain their vibrancy.

Understanding these common mistakes can significantly improve the coloring process and enhance the outcome of your PLA 3D prints.

Related Post: