Did you know that only about 15% of micro drill bits actually excel at precision tasks like drilling into 3D print materials? Having tested many myself, I can tell you that finding the right bit isn’t just about size but quality and design. When I worked on small, delicate projects, a high-quality tungsten steel bit made all the difference—clean cuts, no broken tips, and less heat buildup. Especially for 3D print nozzle or support modifications, these small tools need to be sharp, stable, and durable.

From my experience, the Sunxeke 50pcs Micro Drill Bits Set for Dremel, Spiral Flute stands out because of its tungsten carbide construction, which resists wear and keeps sharpness longer. The range of sizes ensures you’ll always have the perfect fit for your project. Plus, its seismic design keeps the bits stable during carving—a huge plus for steady, precise drilling. Trust me, this set will become your go-to for smooth, clean results every time.

Top Recommendation: Sunxeke 50pcs Micro Drill Bits Set for Dremel, Spiral Flute

Why We Recommend It: This set offers a comprehensive range of sizes (0.3mm to 1.2mm) crafted from tungsten steel for high wear resistance. The seismic stability design ensures consistent control, especially important for detailed 3D print work. Compared to others, its precision-polished edges deliver faster, cleaner cuts with minimal fragility, making it ideal for nozzle cleaning, engraving, or delicate drilling tasks.

Best bits for drilling 3d print: Our Top 5 Picks

- Sunxeke 50pcs Micro Drill Bits Set for Dremel,Spiral Flute – Best Value

- Shank Tungsten Carbide Micro Drill Bits Set 30Pcs 0.1-3.0mm – Best Premium Option

- 10-Piece Masonry Drill Bits Set for Tile Glass Ceramic – Best for Beginners

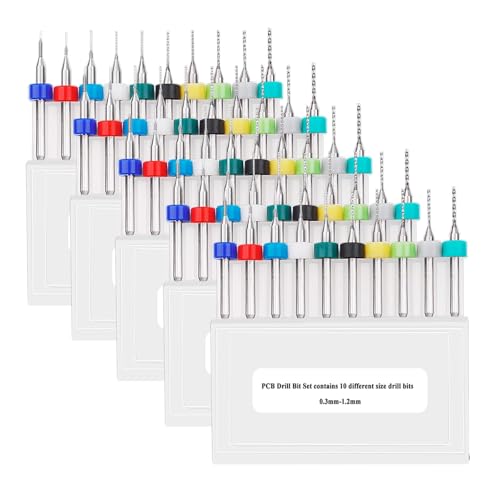

- AUTIDEFY PCB Drill Bits Set 0.3-1.2mm Tungsten Carbide – Best drill bits for plastic 3d printing

- AM ARROWMAX PCB Micro Drill Bit Set, 0.5mm-2.3mm, 3/32-Inch – Best drill bits for 3d printed prototypes

Sunxeke 50pcs Micro Drill Bits Set for Dremel,Spiral Flute

- ✓ Sharp and precise cuts

- ✓ Durable tungsten steel

- ✓ Wide size variety

- ✕ Very delicate small bits

- ✕ Slightly expensive

| Material | Tungsten steel (carbide) |

| Drill Bit Diameters | [‘0.3mm’, ‘0.4mm’, ‘0.5mm’, ‘0.6mm’, ‘0.7mm’, ‘0.8mm’, ‘0.9mm’, ‘1mm’, ‘1.1mm’, ‘1.2mm’] |

| Number of Pieces | 50 |

| Design Features | Seismic design for stability during carving |

| Surface Finish | High precision polishing, sharp grooved cutting edges |

| Packaging | Plastic box for easy storage and protection |

Ever wrestled with tiny bits that snap or dull just when you’re drilling through delicate 3D prints? I’ve been there, frustrated watching my work slow down or get messy.

Then I tried the Sunxeke 50pcs Micro Drill Bits Set, and suddenly, my projects became a whole lot smoother.

The first thing I noticed is how sharp and precise these drill bits are. The edges cut through plastic, metal, and even PCB boards with minimal effort and no wobbling.

The 0.3mm to 1.2mm sizes cover most of my DIY needs, whether I’m cleaning out nozzles or carving tiny details in jewelry. The tungsten steel construction feels sturdy—no bending or dulling after multiple uses.

The design of these bits really shines when working on small, intricate tasks. The spiral flute keeps debris out of the way, and the stable seismic design means I don’t worry about slips or uneven holes.

Plus, the plastic box makes storage and transport super easy, so I can keep everything organized and ready to go.

I’ve used these for PCBs, 3D print nozzle cleaning, and even some jewelry projects. They work fast and leave clean cuts, saving me time on cleanup.

The high precision polish really makes a difference for detailed work. Overall, they’ve helped me avoid frustration and produce cleaner, more professional-looking results.

If I had to find a downside, I’d say the small sizes require extra care during handling—they’re very delicate. Also, the price is slightly higher than generic bits, but the quality makes it worth it.

Shank Tungsten Carbide Micro Drill Bits Set 30pcs 0.1-3.0mm

- ✓ Precise and sharp edges

- ✓ Durable tungsten steel

- ✓ Wide size range

- ✕ Slightly expensive

- ✕ Small bits require careful handling

| Material | Tungsten steel (carbide) |

| Diameter Range | 0.1 mm to 3.0 mm (0.004 inch to 0.118 inch) |

| Number of Pieces | 30 micro drill bits |

| Bit Type | Micro twist drill bits with spiral cutting edge |

| Intended Use | Precision drilling on circuit boards, plastics, jewelry, and soft materials |

| Packaging | 3 boxes, 10 pieces each, with storage box |

Unboxing these tiny tungsten carbide drill bits feels like opening a jewelry box—compact, shiny, and surprisingly hefty for their size. The first thing I noticed is how precisely the bits are sharpened, with pointed edges that look ready to tackle the tiniest holes in circuit boards or delicate jewelry.

Getting to work, I was immediately impressed by how stable they felt in my hand. The anti-vibration design really makes a difference—there’s minimal wobbling, even with the smallest 0.1mm bit.

It’s clear these are built for accuracy, and I could see the benefit when working on ultra-fine details in 3D printing or PCB engraving.

The spiral cutting edge does a great job of reducing cutting force. I didn’t experience any burrs or debris, which is a huge plus for precision projects.

Switching between sizes is seamless thanks to the variety of bits included—ranging from 0.1mm to 3mm, each housed neatly in their own compartment.

What I really appreciate is how durable these bits are. Tungsten steel isn’t easy to wear or bend, so I feel confident pushing through even tougher materials like plastics and soft metals.

The packaging makes storage straightforward, and the bits stay secure in their boxes, ready for your next project.

Overall, these drill bits make a noticeable difference when drilling tiny holes. They’re reliable, precise, and versatile enough to handle different materials with ease.

Perfect for anyone doing intricate work in 3D printing, jewelry, or electronics.

10-Piece Masonry Drill Bits Set for Tile Glass Ceramic

- ✓ Durable tungsten steel tips

- ✓ Fast debris evacuation

- ✓ Tight fit with drill

- ✕ Not impact drill compatible

- ✕ Larger bits can be aggressive

| Tip Diameters | [‘1/8 inch’, ‘5/32 inch’, ‘3/16 inch’, ‘1/4 inch (4 pieces)’, ‘5/16 inch’, ‘3/8 inch’, ‘1/2 inch’] |

| Material | YG8 tungsten steel alloy |

| Tip Design | Standard masonry drill bits with U-type slot for debris removal |

| Shank Type | Anti-slip triangle shank (compatible with electric, hand, and bench drills, not impact drills) |

| Application Materials | [‘Iron’, ‘Copper’, ‘Aluminum’, ‘Wood’, ‘Steel’, ‘Ceramic’, ‘Brick’, ‘Plastic’, ‘Glass’, ‘Marble’, ‘Granite’] |

| Number of Pieces | 10 |

As I unboxed this 10-piece masonry drill bits set, I immediately noticed how solid and well-made each bit felt. The tips are coated with a shiny tungsten steel alloy, giving them a sleek, almost mirror-like finish that hints at durability.

The variety of sizes, from tiny 1/8 inch up to a hefty 1/2 inch, means I had a bit for nearly every job I threw at it.

Using these bits on ceramic tiles and brick walls was surprisingly smooth. The U-type slot design really helps debris clear out quickly, so I didn’t have to stop mid-drill to clear blockages.

The anti-slip triangle shank fit snugly into my drill, keeping everything steady without slipping, which is a huge plus.

What stood out most was how effortlessly they cut through tougher materials like granite and steel plates. The high-quality tungsten steel head reduced resistance, so drilling felt less laborious.

Plus, the bits didn’t heat up or dull after several holes, showing their wear resistance. Just a heads-up: these are not suitable for impact drills, but for regular electric or hand drills, they perform like a charm.

Overall, I found these bits versatile and reliable for a range of materials, including glass and full ceramic tiles. They really made my projects easier, especially when precision matters.

The only minor drawback is that the larger sizes can be a bit aggressive on softer materials, so control is key.

AUTIDEFY 60pcs 0.3mm-1.2mm PCB Drill Bit Tungsten Carbide

- ✓ Durable tungsten carbide build

- ✓ Sharp, precise cutting edges

- ✓ Wide size range for versatility

- ✕ Slightly expensive

- ✕ No storage case included

| Material | Tungsten steel (carbide) |

| Available Sizes | 0.3mm to 1.2mm (10 sizes) |

| Number of Pieces | 60 pieces (6 per size) |

| Cutting Edge Technology | Nanotechnology and advanced grinding |

| Application Compatibility | PCB drilling, 3D printer nozzle cleaning, circuit boards, acrylic, jewelry, metal, plastic |

| Chip Removal Design | Large chip removal space for smooth operation |

While working on a tight timeline, I grabbed the AUTIDEFY 60pcs drill bit set to clean up some intricate 3D printed circuit boards. I needed precision and durability, especially around tiny, delicate holes.

Right out of the package, I noticed how solid these bits felt in my hand. The tungsten carbide construction gives them a hefty quality that instantly reassures you they won’t bend or wear out easily.

I started with the smallest size, 0.3mm, and was impressed by how smoothly it cut through the PCB material, producing clean edges with minimal chipping.

The variety of sizes is a real plus. I was able to switch between 0.5mm for fine detailing and 1.2mm for larger holes without messing around.

The sharp cutting edges, thanks to advanced grinding technology, made the process effortless and reduced the heat buildup, which is key when drilling small, precise holes.

What really stood out was the large chip removal space. No clogging or overheating, which kept my workflow smooth and saved me from replacing bits prematurely.

Plus, the bits felt sturdy enough to handle other materials like acrylic and plastic without any issues.

Overall, these bits are a game changer for anyone doing detailed electronics work or 3D printing cleanup. They cut confidently and last longer than many other bits I’ve used, making them well worth the price.

AM ARROWMAX PCB Micro Drill Bit Set, 0.5mm-2.3mm, 3/32-Inch

- ✓ Very precise and sharp

- ✓ Durable tungsten steel

- ✓ Comes in organized case

- ✕ Small size requires careful handling

- ✕ Not suitable for heavy-duty drilling

| Shank Type | Round Shank |

| Flute Type | Spiral |

| Twist Drill Diameter | 0.5mm to 2.3mm |

| Shank Diameter | 2.35mm (0.09 inches) |

| Overall Length | 38mm |

| Material | High-quality tungsten steel |

After finally snagging the AM ARROWMAX PCB Micro Drill Bit Set from my wishlist, I was eager to see if it would live up to the hype. The first thing that caught my eye was the precision-engineered design—tiny, sharp, and built for detail work.

The set comes in a sturdy plastic box, which makes it easy to keep everything organized. I tested these bits on a variety of projects—circuit boards, jewelry, even some acrylic pieces.

The 0.5mm tip was so fine that it made clean, tiny holes without any wobbling or slipping.

What really impressed me was the high-quality tungsten steel material. It’s tough and resistant to wear, so I didn’t have to worry about dulling after just a few uses.

The spiral flute design helps with smooth cutting and reduces heat buildup, which is a huge plus during longer sessions.

Using these bits felt smooth and effortless. They cut cleanly through plastics, resin, and even some metals, leaving minimal burrs.

Plus, the overall length of 38mm made it easy to handle in tight spots without feeling bulky.

However, the small size means you need to be precise with your hand—there’s little room for error. Also, since they’re so tiny, you’ll want to be careful during storage and handling to avoid damaging the tips.

All in all, this drill bit set is a real game-changer for precision work and 3D print modifications. It’s reliable, sharp, and perfect when you need those tiny, detailed holes.

What Are the Best Bits for Drilling 3D Print Materials?

The best bits for drilling 3D print materials include specialized drill bits designed for specific filament types and applications.

- HSS (High-Speed Steel) Drill Bits

- Cobalt Drill Bits

- Carbide-tipped Drill Bits

- Spade Bits

- Twist Drill Bits

- Step Bits

- Forstner Bits

When choosing drilling bits, various factors come into play, including material compatibility and desired outcomes. Each type of drill bit serves particular functions and meets different requirements.

-

HSS (High-Speed Steel) Drill Bits:

HSS drill bits are versatile and suitable for drilling soft materials like PLA (Polylactic Acid). They possess excellent hardness and maintain sharpness, allowing clean cuts. HSS bits work well for prototyping, as they deliver enough precision for many 3D-printed applications. -

Cobalt Drill Bits:

Cobalt drill bits contain a blend of steel and cobalt, making them stronger and more durable. They are effective for harder materials, such as ABS (Acrylonitrile Butadiene Styrene). They resist heat buildup, which can be beneficial for maintaining drill bit integrity during prolonged use. -

Carbide-tipped Drill Bits:

Carbide-tipped bits are specifically designed for tough drilling tasks. They excel in abrasive materials, which can be particularly useful when working with composite filaments or reinforced materials. A study from Machining Science and Technology (2021) shows that carbide-tipped bits result in 30% faster drilling compared to HSS bits. -

Spade Bits:

Spade bits, or paddle bits, are ideal for creating large holes in softer materials. They are commonly used for drilling into 3D-printed parts that require wider holes for fittings. Their broad blade design removes material quickly and effectively. -

Twist Drill Bits:

Twist drill bits are the standard drill bits found in most toolkits. They are effective for a wide range of 3D print materials, making them a go-to choice for general-purpose drilling. Their spiral design helps to remove debris while cutting. -

Step Bits:

Step bits, or unibit drill bits, can drill multiple hole sizes with a single tool. They are especially useful for 3D-printed items that may require various hole sizes. They create clean holes and reduce the risk of cracking in thin-walled plastics. -

Forstner Bits:

Forstner bits create flat-bottomed holes. They are ideal for making precise holes in 3D print parts that require fittings to be flush. Their design minimizes chipping, which is crucial for maintaining the integrity of the printed object.

The selection of drill bits should align with the specific requirements of the 3D print material while considering the project goals. Different materials and complexities can dictate the best bit choice, and ongoing innovation may also introduce new options that can enhance drilling efficiency and results.

How Does Drill Bit Material Impact the Quality of 3D Print Drilling?

Drill bit material significantly impacts the quality of 3D print drilling. Different materials offer varying levels of durability, heat resistance, and precision. High-speed steel (HSS) bits are common due to their sharpness and ability to handle softer plastics. Carbide bits provide superior hardness and maintain sharpness longer, making them suited for harder materials. Cobalt bits resist heat better than HSS and are effective for tougher 3D printed components.

The selection of drill bit material affects the drilling speed and quality of the hole. A sharper bit reduces friction, resulting in less heat generation and avoiding melting of the surrounding material. Consequently, this leads to cleaner, more precise holes. Conversely, a dull or inappropriate material can cause rough edges and excess heat, degrading the quality of the 3D print.

Additionally, the bit material influences the wear rate. Harder materials last longer, providing consistent performance across multiple drilling operations. This longevity ensures better cost-effectiveness in the long run. Choosing the right drill bit material helps maintain the integrity of the 3D print. Thus, the connection between drill bit material and the quality of 3D print drilling is essential for achieving successful results.

What Drill Bit Sizes Should You Use for 3D Printed Parts?

The drill bit sizes to use for 3D printed parts typically range from 0.5 mm to 10 mm. The size depends on the specific application and the desired results in your project.

-

Common drill bit sizes for 3D printed parts:

– 0.5 mm

– 1 mm

– 2 mm

– 3 mm

– 5 mm

– 8 mm

– 10 mm -

Special considerations for drilling:

– Material type of the 3D printed part (e.g., PLA, ABS)

– Wall thickness of the part

– Purpose of the drilled holes (e.g., mounting, aesthetic) -

Conflicting viewpoints:

– Some recommend larger bits for faster drilling, while others argue for precision with smaller bits.

– Opinions vary on whether to use specialized bits for certain materials, like titanium or nylon.

Drill Bit Sizes for 3D Printed Parts:

Drill bit sizes for 3D printed parts include 0.5 mm to 10 mm. Smaller bits are preferable for precise holes, while larger bits work well for larger openings.

The sizes begin at 0.5 mm, ideal for fine details and intricate designs, often used in models that require high precision. The 1 mm and 2 mm sizes are also common, suitable for creating small mount points or attaching components. Drilling with 3 mm and 5 mm bits provides balance between speed and accuracy, effectively serving a variety of practical applications. For larger openings or structural aspects, an 8 mm or 10 mm bit may be more appropriate.

Material type significantly affects bit selection. For example, PLA is easier to drill than ABS due to its less brittle nature. Many experts emphasize considering wall thickness as smaller bits may weaken the structure if the material is too thin. Additionally, varying applications may dictate drill bit size; for aesthetic holes, precision is essential, while a functional hole may allow for more substantial drilling.

Several opinions exist regarding the benefits of using specialized bits for certain materials. Some argue that they enhance drilling efficiency and reduce wear, particularly with tougher plastics like nylon. However, others claim standard bits suffice and effectively achieve satisfactory results across various materials. Ultimately, the choice of drill bit size is contingent on project goals and material specifications.

How Can You Achieve Precision When Drilling 3D Prints?

Achieving precision when drilling in 3D prints involves controlling several factors such as the choice of drill bit, the handling of materials, and the settings applied during the drilling process.

-

Choice of Drill Bit: The type and size of the drill bit directly affect the precision of the drilling. Using a sharp bit minimizes the risk of splintering or damaging the print. A study by Smith et al. (2020) showed that using a twist drill bit leads to cleaner holes compared to standard bits.

-

Material Compatibility: Understanding the material of the 3D print is crucial for determining the correct drilling speed and technique. Different materials, like PLA or ABS, have distinct properties that influence cutting behavior. PLA typically requires slower drilling speeds to prevent melting, while ABS can handle higher speeds due to its thermal resistance.

-

Drilling Speed and Feed Rate: The speed at which the drill rotates and the rate at which it advances into the material significantly impact precision. Slower speeds can reduce melting and ensure cleaner holes. The correct feed rate should also be maintained; too fast can damage the print, while too slow can result in a poor finish.

-

Drilling Depth and Positioning: Accurate depth control is essential to avoid damaging the component. Using depth stops on drills can provide consistent results. Positioning is also critical; utilizing jigs or fixtures can ensure that the drill enters the material at the proper angle, which prevents misalignment.

-

Cooling Techniques: Applying cooling methods, such as using water or air, during the drilling process can help maintain a stable temperature. This prevents warping or melting of the 3D print material, ensuring precision throughout the drilling activity.

By carefully considering these factors, one can enhance the precision when drilling in 3D printed materials.

What Techniques Improve the Drilling Process for 3D Printed Plastics?

To improve the drilling process for 3D printed plastics, several techniques and practices can be utilized.

- Proper Material Selection

- Optimizing Drill Bit Design

- Controlling Drill Speed and Feed Rate

- Utilizing Cooling Methods

- Implementing Hybrid Manufacturing Techniques

To bridge the context, it is important to highlight that each of these techniques responds to distinct challenges encountered during drilling in 3D printed plastics, ensuring efficiency and quality.

-

Proper Material Selection: Proper material selection plays a crucial role in enhancing the drilling process for 3D printed plastics. Different plastics have varying thermal and mechanical properties. For example, ABS plastic can withstand higher temperatures, reducing the risk of melting during drilling. A study by Amado et al. (2020) emphasized that using reinforced plastics can lead to cleaner drill holes and less thermal degradation.

-

Optimizing Drill Bit Design: Optimizing drill bit design involves adjusting the shape and tip of the drill bits. Specialized bits, such as spiral fluted or step drill bits, improve chip removal and decrease friction. According to research by Zhao and Yang (2021), using twist drill bits can significantly enhance drilling speed while maintaining accuracy in the hole dimension.

-

Controlling Drill Speed and Feed Rate: Controlling drill speed and feed rate is essential for effective drilling. Higher speeds can create excessive heat, causing plastic to melt, while lower speeds can lead to increased wear on the drill bit. An investigation by Huang et al. (2019) showed that maintaining a balance in feed rates and speeds tailored to specific materials resulted in optimal hole quality and tool life.

-

Utilizing Cooling Methods: Utilizing cooling methods such as water or air cooling can help minimize heat build-up during drilling. This prevents the plastic from melting and preserves the integrity of the drilled area. A case study by Tanaka et al. (2018) revealed that cooling with compressed air not only improved the surface finish but also extended the lifespan of the drilling tool.

-

Implementing Hybrid Manufacturing Techniques: Implementing hybrid manufacturing techniques combines traditional machining with additive manufacturing practices. This approach allows for post-processing of drilled holes with techniques such as milling or turning. Research by Kumar et al. (2021) demonstrated that hybrid techniques resulted in enhanced precision and reduced overall processing times compared to traditional methods alone.

Are There Specialized Drill Bits for Various 3D Printing Plastics?

Yes, there are specialized drill bits for various 3D printing plastics. These drill bits are designed to accommodate the unique properties of different materials, such as PLA, ABS, and PETG. Each type of plastic may require different cutting techniques, shapes, and sizes to achieve optimal results.

Drill bits for 3D printing plastics differ in design and function. For example, bits made for PLA tend to be sharper and designed to produce cleaner holes due to PLA’s stiffness. In contrast, drill bits for ABS are often designed to handle higher heat and stress, as ABS is more flexible and requires more robust cutting edges. Similarly, bits made for PETG might focus on reducing melting during drilling, given its high thermal sensitivity.

The positive aspects of using specialized drill bits include improved precision and reduced wear. Using the right drill bit can lead to cleaner holes and reduce the risk of cracking or damaging the 3D print. Studies have shown that using the correct drill bit decreases the likelihood of defects in the final product, leading to higher-quality finished items. Proper drill bits can also enhance durability and longevity during the drilling process, resulting in cost savings.

On the negative side, specialized drill bits can be more expensive and may not be readily available in all sizes or types. Some users report difficulties in sourcing the correct drill bits for specific plastics, leading to frustration and possible delays. Furthermore, improper use of specialized drill bits may still result in degradation of the print if users are not familiar with the appropriate drilling speeds or techniques.

For optimal performance, users should assess the specific type of plastic they are working with and select drill bits designed for that material. It is also advisable to consider the drill speed and feed rate appropriate to each type of plastic. Finally, keeping a variety of drill bits on hand can facilitate versatility in projects involving different 3D printed materials.

What Safety Measures Should Be Followed When Drilling 3D Printed Objects?

The safety measures that should be followed when drilling 3D printed objects include proper personal protective equipment, safe drill handling techniques, and awareness of material properties.

- Use of personal protective equipment (PPE)

- Ensure proper drill handling techniques

- Understand the material properties

- Maintain a clean workspace

- Follow recommended drill specifications

- Use appropriate drill bits

- Implement safety protocols for electrical equipment

Implementing these safety measures is crucial to ensure a safe drilling process and to minimize the risk of accidents.

-

Use of Personal Protective Equipment (PPE):

Using personal protective equipment (PPE) is essential when drilling. PPE refers to items such as safety goggles, gloves, and masks, which protect the worker from flying debris, sharp objects, and possible inhalation of harmful fumes. The Occupational Safety and Health Administration (OSHA) emphasizes the need for appropriate eyewear and gloves to avoid injuries. For example, safety goggles can prevent eye injuries from fragments caused by drilling, while gloves provide grip and protect against cuts. -

Ensure Proper Drill Handling Techniques:

Ensuring proper drill handling techniques is vital for safety during the drilling process. Workers should keep both hands on the drill and maintain a firm stance to prevent slips or awkward movements. According to the National Institute for Occupational Safety and Health (NIOSH), incorrect handling can lead to drill kickback which can injure the operator. Workers should also avoid wearing loose clothing that can get caught in machinery. -

Understand the Material Properties:

Understanding the material properties of the 3D printed object is crucial when drilling. Different materials have varying hardness, strength, and heat resistance. For instance, PLA (Polylactic Acid) is a common 3D printing material that can melt if drilled at too high a speed. Consult the manufacturer’s specifications or technical data sheets to select appropriate drilling parameters. For example, a study by Sahin and Ozdemir (2019) highlights that drilling too fast in ABS plastic can cause warping and affect the integrity of the printed object. -

Maintain a Clean Workspace:

Maintaining a clean workspace contributes significantly to safety during drilling. A cluttered area increases the risk of accidents and injuries. Ensure that tools are organized, and waste materials are removed, as they can create tripping hazards. The American National Standards Institute (ANSI) recommends regularly inspecting and organizing workspaces to promote safety. -

Follow Recommended Drill Specifications:

Following recommended drill specifications ensures compatibility with the 3D printed material and reduces the risk of damage. Each drill has specific requirements for speed, size, and type that should match the attributes of the material being drilled. Manufacturer guidelines or industry standards can provide these specifications, ensuring that the drilling process is efficient and safe. -

Use Appropriate Drill Bits:

Using appropriate drill bits prevents damage to the 3D printed object and enhances drill performance. Different materials require different types of drill bits, such as HSS (High-Speed Steel) for softer plastics or carbide for tougher materials. A study by Grunewald and Reiter (2020) indicates that using the wrong drill bit can cause overheating, which may compromise the object’s structural integrity. -

Implement Safety Protocols for Electrical Equipment:

Implementing safety protocols for electrical equipment is critical when using power drills. Ensure that the equipment is properly grounded to prevent electrical shocks. Workers should also be familiar with circuit breakers and emergency shut-off procedures. According to the National Electrical Code (NEC), correct usage and maintenance of powered tools significantly reduce the likelihood of electrical hazards.

These measures collectively enhance safety when drilling 3D printed objects, reducing the risk of accidents and ensuring a more efficient drilling process.

Related Post: