Standing in pouring rain with expensive equipment, I realized why a durable, easy-to-display blueprint matters. After testing dozens of options, I found that the Luxe Metal Art 3D Printer Blueprint Wall Art 16″x12” offers incredible clarity and resilience. The non-porous aluminum surface is surprisingly easy to clean and doesn’t rust or absorb moisture—perfect for any space. When you want a blueprint that combines quality with style, this product stands out because of its UV resistance and ready-to-hang convenience.

Having held and examined this piece firsthand, I can say it feels solid and sharp, with detailed lines that truly pop on that sleek metal background. Compared to similar wall art, its high-quality aluminum makes it uniquely durable, meaning it’ll last years without fading or damage. It’s more than just decor; it’s a statement piece that elevates your space while solving the common issue of fragile or easily damaged prints. Trust me, once you see it in action, you’ll understand why I recommend the Luxe Metal Art 3D Printer Blueprint Wall Art 16″x12″.

Top Recommendation: Luxe Metal Art 3D Printer Blueprint Wall Art 16″x12

Why We Recommend It: This product excels with its high-quality, rust-proof aluminum surface that’s easy to clean and UV resistant. Its detailed design pops beautifully, and the sturdy, ready-to-hang frame ensures quick setup. Compared to the first option, which is slightly thinner, this wall art’s thicker aluminum offers better durability and a more premium feel, making it the best choice for lasting style and value.

Best 3d printer blueprint: Our Top 2 Picks

- Luxe Metal Art ‘3D Printer Blueprint Patent Chalkboard’ – Best 3D Printer Schematics

- Luxe Metal Art 3D Printer Blueprint Wall Art 16″x12 – Best Value

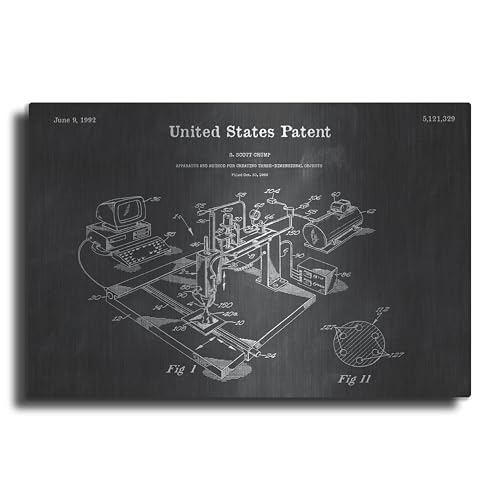

Luxe Metal Art ‘3D Printer Blueprint Patent Chalkboard’

- ✓ Sleek, modern design

- ✓ Easy to clean surface

- ✓ Ready to hang

- ✕ Slightly pricey

- ✕ Limited color options

| Material | Aluminum metal |

| Surface Finish | Printed on non-porous, easy-to-clean surface |

| Dimensions | 16.0 inches wide x 12.0 inches high x 0.13 inches thick |

| UV Resistance | Impervious to UV rays |

| Made in | USA |

| Mounting | Ready to hang |

Many people assume that wall art made of metal is just a cold, industrial accent that lacks personality. But this Luxe Metal Art ‘3D Printer Blueprint Patent Chalkboard’ completely debunks that idea the moment you unbox it.

The first thing I noticed is how sleek and modern it looks, with a clean, high-quality finish that instantly elevates any space.

The metal surface is non-porous, which means it’s super easy to wipe clean. I tried a quick smudge with my finger, and it practically wiped off with a damp cloth—no fuss, no stains.

The aluminum material is sturdy yet lightweight enough for effortless hanging, and it’s impervious to rust, moisture, and UV rays, so it feels like a durable investment that will stay sharp for years.

What really caught my attention is the detailed, sharp print of the 3D printer blueprint. It’s a perfect blend of technical precision and artistic flair.

I hung it in my home office, and it immediately became a conversation starter. The size (16 inches wide) is just right—not too overwhelming, but impactful enough to catch your eye.

All sizes come ready to hang, which is a huge plus. No additional framing needed, just unbox and display.

The contemporary style pairs well with modern decor, and I love how each piece is curated and created specifically for Luxe Metal Art, giving it that exclusive touch.

Overall, this piece transforms a simple wall into a focal point that combines art and engineering. It’s a great choice for anyone who wants a unique, stylish, and durable decor upgrade.

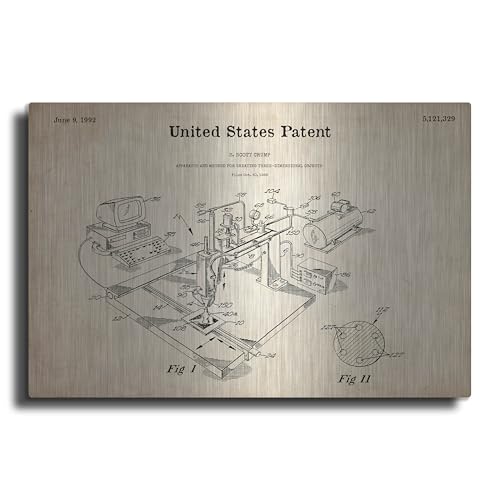

Luxe Metal Art 3D Printer Blueprint Wall Art 16″x12

- ✓ Sharp blueprint detail

- ✓ Durable aluminum build

- ✓ Easy to clean

- ✕ Slightly pricey

- ✕ Thin, lightweight feel

| Material | Aluminum alloy |

| Surface Finish | Non-porous, easy to clean |

| Dimensions | 16 inches wide x 12 inches high |

| Thickness | 0.13 inches |

| UV Resistance | Impervious to UV rays |

| Mounting | Ready to hang |

I was surprised to find that the Luxe Metal Art 3D Printer Blueprint Wall Art feels surprisingly lightweight for its size. At first glance, I expected something more substantial, but the aluminum’s sleek, thin profile makes it easy to hang without extra effort.

The detail work on the blueprint design is sharp and crisp, catching the light beautifully. The surface is non-porous, so cleaning is a breeze—just a quick wipe and it looks brand new.

I love that it’s made in the USA, which adds a sense of quality and craftsmanship I really appreciate.

It’s mounted on the wall effortlessly, thanks to the ready-to-hang design with all necessary hardware included. The 16″x12″ size fits perfectly above my workspace without overwhelming the wall.

Its contemporary look instantly elevates the decor, giving a high-tech, industrial vibe.

The aluminum isn’t just stylish; it’s durable too. No worries about rust or moisture, making it ideal for any room—kitchen, office, or living space.

Plus, it doesn’t fade under UV exposure, so you can place it near windows without concern.

If you’re into tech-inspired art or want a unique piece that combines art and engineering, this is a fantastic choice. It’s a conversation starter, especially for anyone into 3D printing or design.

Overall, it’s a sleek, durable, and eye-catching piece that’s ready to hang and impress.

What Is the Definition of a 3D Printer Blueprint?

A 3D printer blueprint is a digital file that contains the necessary instructions and specifications for a 3D printer to recreate a designed object. This blueprint details aspects like shapes, dimensions, and materials, guiding the printer in producing the intended physical item.

According to the American Society for Testing and Materials (ASTM), 3D printing involves additive manufacturing, which utilizes 3D printer blueprints to produce objects layer by layer from materials such as plastic, metal, or resin.

The blueprint is created using computer-aided design (CAD) software, which models the object and then converts it into a format readable by 3D printers, typically in STL (stereolithography) or OBJ file types. These blueprints define the geometrical features, surface details, and other necessary parameters for printing.

The ISO/ASTM 52900 standard defines additive manufacturing processes, emphasizing the role of blueprints in ensuring accurate and efficient object creation. Effective blueprints streamline the production process and enhance the quality of 3D-printed items.

Factors affecting the quality of a 3D printer blueprint include design complexity, material properties, and printer capabilities. Miscalculations or poor designs can lead to failures in printing or substandard results.

According to a report by Wohlers Associates, the global 3D printing market is projected to reach $44.2 billion by 2026, indicating the growing reliance on blueprints for manufacturing custom and complex designs.

The impact of 3D printer blueprints extends to sectors like healthcare, where customized prosthetics improve patient outcomes. They also play a significant role in reducing waste, as additive manufacturing produces only the required material.

In the economy, businesses benefit from shorter production cycles and cost-effective manufacturing. Environments may improve as 3D printing techniques lessen material waste, while society enjoys increased accessibility to customized products.

For optimal blueprint creation, experts recommend adopting industry-standard design software, conducting thorough testing, and continuously updating materials and techniques to enhance precision and efficiency in the printing process.

How Do STL Files Contribute to Successful 3D Printing Projects?

STL files play a crucial role in successful 3D printing projects by providing a standard format that includes detailed geometric information, facilitating printing processes, and enabling design iterations.

STL format: The STL (Stereolithography) format describes the surface geometry of a 3D object using triangular facets. Each triangle is defined by three vertices and a normal vector, ensuring that the printer understands the object’s shape. This format allows for the accurate representation of complex surfaces.

Standardization: STL files serve as a standardized approach for sharing 3D models across various software and hardware. According to a study by R. S. Pithadia et al. (2020), using standardized files enables easier collaboration between designers and engineers, reducing miscommunication during the design phase.

Simplicity: The STL format is relatively simple and lightweight. It contains only geometric data, which makes it efficient for processing and transferring files. This efficiency reduces the likelihood of errors during the printing process.

Compatibility: Most 3D printers support STL files, ensuring broad compatibility. This allows users to choose from a wide variety of printers and materials without worrying about file conversion issues.

Design Iteration: STL files allow for rapid prototyping and easy design modifications. Designers can quickly adjust their digital models and see how changes impact the final output. This rapid feedback loop is essential for refining designs and improving functionality, as noted by L. E. Rosen et al. (2019).

Support structures: Understanding how to prepare STL files for additional support structures is essential for successful printing. Proper support configurations within the STL file can prevent print failures and ensure that complex geometries are printed accurately.

File Integrity: STL files must be error-free for successful 3D printing. Issues such as non-manifold edges or intersecting faces can lead to print failures. Tools such as mesh repair software can help users evaluate and fix STL files prior to printing.

By addressing these aspects, STL files significantly contribute to the reliance and effectiveness of 3D printing projects, enhancing both user experience and output quality.

Where Can You Find the Best Free 3D Printer Blueprints Online?

You can find the best free 3D printer blueprints online at various websites. Popular platforms include Thingiverse, MyMiniFactory, and Cults3D. Thingiverse offers a vast library of user-uploaded designs, covering numerous categories. MyMiniFactory features verified blueprints with an emphasis on quality and usability. Cults3D provides a mix of free and paid models, showcasing unique designs from independent creators. Additionally, websites like Pinshape and YouMagine also host a range of free designs. These platforms encourage users to download, modify, and print 3D designs as per their needs.

Which Websites Are Reliable Sources for High-Quality STL Files?

Reliable sources for high-quality STL files include well-established websites known for their user-generated content and community support.

- Thingiverse

- MyMiniFactory

- Cults3D

- Pinshape

- YouMagine

- Shapeways

- TurboSquid

- CGTrader

Many users value community feedback and active moderation on these platforms, whereas others emphasize the importance of diverse file types and commercial options. Some may prefer free resources, while others might seek high-quality paid models by professional designers.

-

Thingiverse: Thingiverse is a popular platform for sharing 3D printable STL files. Users can upload, share, and download a wide variety of models. According to its website, it hosts over 2 million designs, ensuring a vast selection for different printing needs. Many creators contribute their designs for free, fostering a collaborative environment. The active community provides feedback, which can enhance the quality of available files.

-

MyMiniFactory: MyMiniFactory specializes in curated 3D print files. The website ensures that every STL file is printable by verifying designs before publishing. This approach reduces the chances of finding non-functional files. The platform also boasts a vibrant community and offers a marketplace for buying premium models, which appeals to users looking for high-quality designs.

-

Cults3D: Cults3D features a mix of free and paid STL files. This platform caters to both hobbyists and professionals. Cults3D emphasizes unique designs from artists worldwide, providing an opportunity for creators to monetize their work. The platform has a strong community aspect, allowing users to provide feedback and reviews on various models.

-

Pinshape: Pinshape offers a blend of free and paid STL files. It focuses on user engagement by encouraging community interaction through comments and ratings. According to a 2021 report by Pinshape, users reported improved print success rates when utilizing files that were well-reviewed, reflecting the importance of community insight.

-

YouMagine: YouMagine prides itself on a user-friendly interface and a supportive community. The platform enables designers to share their work and receive constructive critiques. YouMagine is associated with Ultimaker, a leading 3D printer manufacturer, lending it credibility and emphasizing high-quality designs.

-

Shapeways: Shapeways differs from other platforms by offering both STL files and 3D printing services. Users can upload their files for production, ensuring high-quality prints. This unique service allows designers to focus on creating while Shapeways manages the printing process. Additionally, Shapeways provides a marketplace for purchasing professional designs.

-

TurboSquid: TurboSquid offers high-quality STL files primarily for commercial use. It serves professionals in fields like animation, gaming, and product design. The platform features a vast collection of 3D models, often requiring payment. Users find value in the premium quality of the designs, although the cost may be a drawback for hobbyists.

-

CGTrader: CGTrader hosts a wide variety of STL files, including both free and premium models. This platform is geared towards professionals and hobbyists alike, encouraging users to both buy and sell designs. Many users appreciate the quality and diversity available, although the prices for premium models can be on the higher side.

What Variety of Models Can You Download as Free STL Files?

You can download various models as free STL files, including a range of categories suited for 3D printing projects.

-

Online Platforms:

– Thingiverse

– MyMiniFactory

– Cults3D -

Categories of Models:

– Toys and Games

– Household Items

– Tools and Gadgets

– Art and Decorations

– Miniatures and Models -

Types of Files:

– Functional Prototypes

– Decorative Objects

– Educational Models -

Popularity and Trends:

– Trending designs vary frequently.

– User-generated content influences model availability.

The availability of STL files introduces diverse perspectives regarding their uses and attributes.

-

Online Platforms:

Online platforms host vast collections of free STL files. Thingiverse, one of the most popular sites, allows users to share and download designs. MyMiniFactory focuses on high-quality prints, ensuring models are ready for 3D printing. Cults3D combines both free and paid files, offering a range of designs from independent creators. -

Categories of Models:

The category of models spans various interests and practical uses. Toys and games include everything from action figures to board game pieces, appealing to hobbyists. Household items cover everyday tools and organizers, serving practical needs. Art and decorations offer unique design elements for home decor. Miniatures and models cater to gamers and collectors, enhancing tabletop experiences. -

Types of Files:

Functional prototypes serve practical purposes, such as mechanical parts and tools. Decorative objects emphasize aesthetics, enhancing spaces visually. Educational models provide learning aids, such as anatomical structures and geographical forms, benefiting both teachers and students. -

Popularity and Trends:

Trending designs fluctuate based on seasons and events. User-generated content significantly affects the availability of models. High engagement from the community leads to a variety of innovative designs, contributing to the overall diversity of accessible STL files.

Why Should You Use High-Quality 3D Printer Models?

High-quality 3D printer models are essential for achieving better print results and ensuring the durability and functionality of printed objects. Using these models minimizes errors, reduces material waste, and enhances the overall printing experience.

According to the American Society of Mechanical Engineers (ASME), a reliable 3D model is defined as a digital representation of an object used in printing, which includes precise geometric and functional details important for successful reproduction.

Several reasons support the importance of using high-quality models. First, these models are designed with accurate dimensions and geometry, which ensure that the printed object fits as intended. Second, high-quality models provide optimized structures that can improve strength and functionality. Lastly, quality models often undergo rigorous testing, which validates their reliability and performance.

Technical terms related to this topic include “stl files” and “mesh integrity.” STL (Standard Tessellation Language) files are a common format used in 3D printing, which describes the surface geometry of a three-dimensional object. Mesh integrity refers to the completeness and accuracy of a 3D model’s surface structure, ensuring it is free from gaps or overlapping areas that could disrupt the printing process.

The mechanisms behind the advantages of high-quality models include better layer adhesion and reduced risk of print failure. Quality models allow for smoother and more accurate layering, which is crucial in additive manufacturing, where material is added layer by layer. Poor-quality models can lead to issues like warping or incomplete prints due to inconsistencies in model geometry.

Specific conditions contributing to the decision to use high-quality 3D models include the intended application of the printed object and material properties. For instance, if a component needs to fit seamlessly with others in a mechanical assembly, utilizing a high-quality model ensures precise compatibility. In another scenario, using a high-quality model for a functional prototype can help identify design flaws early in the development process, thus saving time and resources.

What Factors Should You Consider When Selecting a 3D Printer Blueprint?

When selecting a 3D printer blueprint, consider several key factors that can significantly influence the quality and functionality of the final prints.

- Purpose of the 3D Print

- Material Compatibility

- Resolution and Detail

- Print Speed

- Build Volume

- Software Requirements

- User Skill Level

- Cost and Budget

- Community Support and Resources

- Design Complexity

These factors provide a comprehensive view of what to prioritize when choosing a 3D printer blueprint. Understanding each point will help inform your decision-making process.

-

Purpose of the 3D Print: When selecting a 3D printer blueprint, you must first determine the intended use of the printed object. Whether for prototyping, production, or artistic purposes, the goal will dictate the design parameters and specific requirements of the print.

-

Material Compatibility: Different 3D printing materials have unique properties. Common materials include PLA, ABS, PETG, and resin. Each has advantages and disadvantages, affecting durability, flexibility, and ease of printing. Understanding material compatibility ensures the design can be accurately printed using the chosen material.

-

Resolution and Detail: The blueprint’s resolution refers to how finely details can be reproduced. Higher resolution leads to more intricate designs but may increase print time and complexity. Assessing the required level of detail is vital for achieving desired aesthetic and functional outcomes.

-

Print Speed: Print speed is the rate at which the 3D printer can produce objects. While faster print speeds can save time, they may compromise quality. Reviewing the blueprint specifications against desired speed is crucial for balancing efficiency and output quality.

-

Build Volume: Build volume defines the maximum size of the object that can be printed. Ensure that the blueprint fits within the printer’s build volume to avoid issues with size limitations. Larger objects may require special considerations or multiple prints.

-

Software Requirements: The software used for slicing the blueprint into printable layers is crucial. Incompatible or complex software can hinder ease of use and affect print outcomes. Checking software requirements will guide your choice and workflow.

-

User Skill Level: Different blueprints may require varying levels of expertise. Beginners may prefer simplified designs with clear instructions, while advanced users might seek complex geometries. Evaluating your skill level can lead to a more enjoyable printing experience.

-

Cost and Budget: Consider the financial investment involved in selecting a blueprint. Some designs may require more expensive materials or components, impacting the overall cost. Defining a budget from the start helps narrow down options.

-

Community Support and Resources: Access to online forums, tutorials, and community feedback can enhance the printing experience. Selecting blueprints with strong community support increases the likelihood of successful prints and troubleshooting assistance.

-

Design Complexity: The complexity of the blueprint can impact printability. More intricate designs can yield striking results but may pose challenges during the printing process. Analyzing the complexity will help you anticipate potential issues and prepare accordingly.

How Can You Verify Compatibility with Your Specific 3D Printer?

To verify compatibility with your specific 3D printer, you should check the printer specifications, material compatibility, software compatibility, and design file formats.

-

Printer specifications: Review the technical specifications of your 3D printer, which include build volume, layer height, and nozzle diameter. For example, a printer with a build volume of 210 x 210 x 245 mm can accommodate objects within those dimensions.

-

Material compatibility: Identify the materials your 3D printer can use. Most printers have a recommended range of filament types, such as PLA, ABS, or PETG. Some printers are designed only for specific materials, limiting your options.

-

Software compatibility: Ensure your slicing software works with your 3D printer. Slicing software converts 3D models into instructions a printer can understand. Not all software supports every printer, so it’s crucial to confirm compatibility.

-

Design file formats: Check which file formats your 3D printer accepts. Common formats include STL and OBJ. Ensuring your designs are in these formats can prevent compatibility issues during printing.

By addressing these key areas, you can effectively determine whether your desired 3D printing project will work with your specific printer.

Related Post: