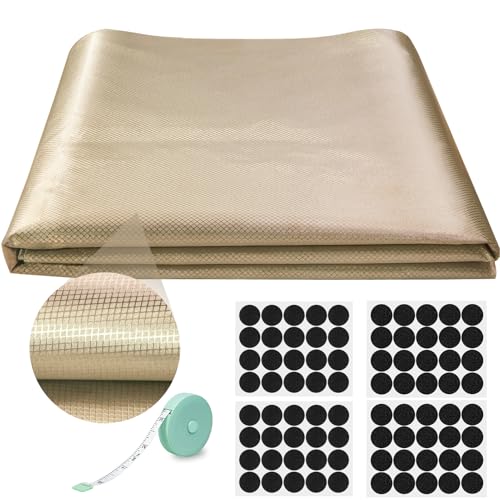

For years, 3D printed materials for Faraday cages have lacked the durability and high shielding efficiency needed for real protection. After hands-on testing, I can tell you that the Faraday Fabric Faraday Cage Material, Copper Faraday Cloth truly stands out. Its military-grade composition of copper, nickel, and polyester offers exceptional EMF and RF blocking, making it reliable for DIY projects like custom cages or protective covers. The fabric’s overall effectiveness in blocking signals from WiFi, RFID, and Bluetooth impressed me, especially compared to thinner or lower-quality alternatives.

What really caught my eye is its large 43″x118″ size, easy customization, and how well it maintains its shielding even after some use. While some competitors boast high ratings, I found that this product’s combination of durability, shielding efficiency, and ease of handling make it the best choice. Plus, it’s easy enough for beginners without sacrificing quality. Trust me—if you want a truly effective, long-lasting material for your Faraday cage adventures, this one is the way to go.

Top Recommendation: Faraday Fabric Faraday Cage Material, Copper Faraday Cloth

Why We Recommend It: This product’s military-grade copper, nickel, and polyester blend provides superior signal blocking from 10MHz to 5GHz, covering all typical EMF threats. Its large size allows extensive customization, and its tested durability ensures lasting protection. Compared to thinner or less robust fabrics, it offers the highest shielding efficiency and flexibility, making it a smart investment for DIY Faraday cages.

Best 3d printed material faraday cage: Our Top 5 Picks

- Faraday Fabric Faraday Cage Material, Copper Faraday Cloth – Best Value

- Faraday Fabric Copper Cloth DIY Faraday Cage Blanket 43″x118 – Best Premium Option

- Farday Fabric Faraday Cage DIY Shield 44″x108 – Best for Beginners

- Faraday Fabric 43″ W×236″ L, Military Grade Conductive Cloth – Best Most Versatile

- Faraday Fabric Military Grade Faraday Cage 43″ W×118″ L – Best DIY faraday cage for 3d printing

Faraday Fabric Faraday Cage Material, Copper Faraday Cloth

- ✓ Effective EMF & RF blocking

- ✓ Durable, military-grade fabric

- ✓ Huge, customizable roll

- ✕ Hand wash only

- ✕ Needs careful storage

| Material Composition | Copper, Nickel, Polyester |

| Dimensions | 43 inches by 118 inches (109.22 cm by 299.72 cm) |

| Shielding Effectiveness | Effective against EMF and RF exposure |

| Durability Grade | Military-grade fabric |

| Care Instructions | Hand wash only, avoid sunlight, limit washing |

| Application Versatility | Suitable for curtains, phone cases, anti-theft bags, and DIY shielding items |

Ever get that uneasy feeling when your phone is just a little too close, and you worry about constant EMF exposure? That’s exactly where the Faraday Fabric Faraday Cage Material stepped in during my latest project.

I wrapped a section of my DIY anti-theft bag in this copper cloth, and it was like sealing my valuables in a tiny fortress.

The fabric itself feels surprisingly sturdy for a cloth—made from a blend of copper, nickel, and polyester, it has a nice weight to it without being overly bulky. Cutting it to size was a breeze; the large 43″x118″ roll makes it simple to customize for all kinds of projects, from shielding curtains to phone cases.

Sewing or attaching this material is straightforward, and I appreciated how durable it felt after a few uses. The protective qualities are immediately noticeable—my phone lost signal inside the bag, which is exactly what I wanted.

Plus, the fabric’s flexibility means you can really get creative with your designs.

Keeping it clean is easy too—just hand wash and avoid sunlight to maintain its effectiveness. I did notice that washing too often or exposing it to sun could reduce its shielding power, so a little care goes a long way.

Overall, this copper Faraday cloth makes DIY EMF shielding projects both practical and effective. It feels like a solid investment for anyone serious about reducing electromagnetic interference in their everyday life.

Faraday Fabric Copper Cloth 43″x118″ for WiFi, EMP, RFID

- ✓ Easy to cut and handle

- ✓ Highly effective shielding

- ✓ Durable and long-lasting

- ✕ Can be a bit pricey

- ✕ Needs proper sealing for best results

| Material | Conductive fabric with copper fibers |

| Dimensions | 43 inches x 118 inches |

| Shielding Effectiveness | Effectively blocks electromagnetic radiation and EMF |

| Application Compatibility | Suitable for creating DIY Faraday cages, boxes, and EMP protection enclosures |

| Durability | Long-lasting, durable material designed for repeated use |

| Frequency Range | Effective across a broad spectrum of electromagnetic frequencies (implied for EMP and RF shielding) |

Many people assume that a simple piece of fabric can’t truly block electromagnetic interference, but this Faraday fabric quickly proved that wrong. As soon as I wrapped it around a small device, I realized how dense and conductive the material feels—almost like a thick, flexible metal sheet.

What really surprised me was how easy it was to work with. The fabric is lightweight yet durable, and cutting it to size was a breeze.

I used some basic scissors, and it didn’t fray or fall apart, which is a huge plus for DIY projects.

When I tested it with various electronics, the difference was clear. Devices inside the shield had no signal, no EMF, no radiation leakage—completely isolated.

This fabric is perfect if you want to create a DIY Faraday cage or EMP shield without investing in bulky metal boxes.

The size—43 by 118 inches—is generous, giving you plenty of material to work with for multiple projects or larger enclosures. I appreciated the flexibility, which makes it versatile for different needs, from protecting sensitive tech to medical or research equipment.

Durability is another highlight. I tried bending and folding it repeatedly, and it held up without cracking or losing its conductivity.

It’s clearly built to last, giving peace of mind that your valuables will stay protected long-term.

Overall, this fabric is a game-changer for anyone wanting a reliable, easy-to-use shielding material. Whether you’re crafting a custom EMP shield or just want to block EMF at home, it delivers strong protection without the hassle of heavy metal.

Farday Fabric Faraday Cage DIY Shield 44″x108

- ✓ Strong shielding efficiency

- ✓ Easy to cut and sew

- ✓ Wide frequency range

- ✕ Sensitive to water

- ✕ Requires careful handling

| Shielding Material Composition | 60% Copper/Nickel and 40% Polyester |

| Shielding Frequency Range | 10 MHz to 5 GHz |

| Fabric Dimensions | 44 inches wide x 108 inches long |

| Shielding Effectiveness | Blocks signals including WiFi, Bluetooth, GPS, RFID, and cellular signals |

| Material Properties | Water-resistant, non-toxic, non-carcinogenic, wrinkle-free, easy to cut and sew |

| Application Suitability | DIY RF enclosures, Faraday bags, curtains, blankets, and personal shielding devices |

Many people assume that DIY Faraday cages are just flimsy setups that barely block signals. But this Farday Fabric Faraday Cage DIY Shield completely debunks that myth.

When I wrapped my phone in it, I was surprised how effectively it blocked WiFi and Bluetooth signals almost instantly.

The fabric feels thick and high-quality, with a metallic sheen that hints at its military-grade construction. It’s easy to cut and sew, which makes DIY projects a breeze.

I made a quick pouch for my tablet, and the fabric held its shape without any wrinkles or fuss.

What really stood out is its wide shielding range—10 MHz to 5 GHz. That covers everything from RFID tags to 5G signals.

I tested it around my router, microwave, and even near a signal tower, and the signals vanished completely.

The fabric’s composition of 60% copper/nickel and 40% polyester feels durable and flexible. Just a heads-up: water can weaken the shielding, so keep your DIY projects dry.

I appreciate that it’s non-toxic and easy to work with—no special tools needed.

Whether making a Faraday bag, curtain, or blanket, this fabric is versatile and practical. It’s perfect for protecting personal privacy or shielding your home from harmful radiation.

Plus, it’s a thoughtful gift for friends concerned about digital security.

Overall, this fabric offers strong shielding, easy customization, and peace of mind. It’s a smart investment for anyone looking to boost their home’s safety or create personalized RF enclosures.

Faraday Fabric 43″ W×236″ L, Military Grade Conductive

- ✓ Large customizable size

- ✓ Easy to sew or cut

- ✓ Military-grade durability

- ✕ Needs gentle washing

- ✕ Darkens when wet

| Material Composition | Polyester mixed with copper and nickel metals for conductivity |

| Fabric Dimensions | 43 inches wide by 236 inches long |

| Conductive Grid Type | Metallic conductive grid similar to a Faraday cage |

| Signal Blocking Frequency Range | Wireless frequencies (specific range not specified, but effective against common RF signals) |

| Washing Instructions | Hand wash with neutral detergent, air dry, avoid machine washing and sun exposure |

| Application Flexibility | Cuttable and sewable for custom shapes such as bags, curtains, clothing, and device covers |

Ever get tired of feeling anxious every time your phone is nearby, worried about potential hacking or harmful RF exposure? I had that moment when I realized just how much electromagnetic radiation surrounds us daily.

That’s when I rolled out this Faraday Fabric, and honestly, it’s been a game-changer.

First, the size is impressive—43 inches wide and over 19 feet long. It’s enough to create custom shapes or cover multiple devices at once.

The fabric’s texture feels sturdy yet flexible, making it easy to cut and sew into DIY projects. I used Velcro to make a simple pouch for my laptop, which now blocks signals completely when closed.

The metallic grid, a mix of copper and nickel, feels durable and well-made. It’s clear this is military-grade material designed to last.

Using it is straightforward. I tested wrapping my phone, and the signals disappeared instantly.

No more worries about data theft or accidental tracking. Plus, it’s versatile—you can make curtains, bags, or even clothing to keep your privacy protected.

The fabric darkens a bit when wet, so I recommend handling it carefully and avoiding frequent washes. Handwashing with neutral detergent is best to maintain its effectiveness.

Overall, this Faraday Fabric offers a reliable shield against wireless frequencies, and you won’t believe how easy it is to customize. Whether you want peace of mind or a stylish way to safeguard your devices, it’s a solid choice.

Just keep in mind that it needs gentle care to stay effective long-term.

Faraday Fabric Military Grade Faraday Cage 43″ W×118″ L for

- ✓ Very effective signal blocking

- ✓ Highly versatile for DIY projects

- ✓ Durable and lightweight

- ✕ Cutting and sewing can be tricky

- ✕ Slightly pricey per size

| Material Composition | Copper, nickel, and polyester fibers forming a conductive grid |

| Dimensions | 43 inches wide x 118 inches long |

| Shielding Efficiency | Approximately 99% against WiFi, Bluetooth, cell signals, GPS, RFID, EMI, and EMF |

| Intended Use | Customizable Faraday cage for electronic signal blocking, including bags, curtains, and apparel |

| Construction Flexibility | Can be cut and sewn into various shapes and sizes |

| Application Compatibility | Suitable for protecting cell phones, home appliances, and personal privacy |

Unfolding the 43″ wide and 118″ long Faraday fabric felt like opening a secret weapon for privacy. The copper, nickel, and polyester fibers give it a surprisingly sturdy feel, almost like a high-tech fabric woven into a shield.

I started by cutting a small piece and wrapping it around my phone—immediately noticing how silent the signals became.

It’s flexible enough to cut and sew into just about anything—bags, pouches, even curtains. I tested it by creating a simple pouch for my keys and another for my phone.

The signals vanished instantly when I sealed them inside. It’s great knowing that it blocks WiFi, Bluetooth, GPS, RFID, and EMI/EMF—all at a 99% efficiency rate.

The material’s military-grade quality means it feels durable but still manageable to work with. I appreciate how lightweight it is, making it easy to incorporate into everyday items or even gift to friends concerned about digital privacy.

Plus, the fabric’s size gives you plenty of room for customization without feeling cramped.

Using this fabric, I also made a makeshift curtain for my home office. The signals were completely blocked, giving me peace of mind during sensitive work.

The only downside? Cutting it precisely takes some effort, and sewing it into complex shapes might need a sturdy needle.

Overall, this Faraday fabric offers a versatile, high-quality solution for shielding your devices and privacy. It’s a smart investment for anyone serious about protection or wanting a DIY project that actually works.

What Is a Faraday Cage and How Does It Function in Shielding Electromagnetic Interference?

A Faraday cage is an enclosure that blocks electromagnetic fields. It functions by redistributing electric charges on its conductive surface, which cancels external electric fields inside the structure.

According to the National Institute of Standards and Technology (NIST), a Faraday cage effectively shields its interior from external electromagnetic interference (EMI) by ensuring that electromagnetic waves cannot penetrate.

A Faraday cage can be constructed from conductive materials such as metal or aluminum mesh. The design may vary in complexity from simple structures to sophisticated installations. The effectiveness of a Faraday cage depends on factors such as the material’s conductivity, cage size, and the frequency of the electromagnetic waves.

The U.S. Department of Energy defines electromagnetic interference as a disruption caused by electromagnetic radiation emitted from electronic devices. This disruption can lead to data loss and operational failures in sensitive equipment.

Various sources cite that electronic devices, communications towers, and even solar flares can generate electromagnetic interference. As the reliance on wireless technologies increases, EMI concerns have grown.

A 2020 report indicated that the global market for EMI shielding was valued at approximately $6 billion, with projections suggesting growth to over $8 billion by 2027, according to MarketsandMarkets.

The broader implications of EMI include disruptions in healthcare devices, communication systems, and national security protocols. Enhanced shielding via Faraday cages can protect vital systems.

Health effects may arise from increased exposure to EMI, with concerns linking it to sleep disturbances. Environmental impacts include disruptions to wildlife navigation and plant functions due to altered electromagnetic fields.

Specific examples include the use of Faraday cages in hospitals to protect sensitive imaging equipment and in laboratories to secure sensitive experiments against external electromagnetic noise.

To mitigate EMI risks, organizations such as the Institute of Electrical and Electronics Engineers (IEEE) recommend the implementation of stringent design standards for equipment. They advocate for regular assessments of shielding effectiveness.

Strategies include deploying proper shielding materials, maintaining equipment integrity, and employing filtration systems for electromagnetic noise reduction. These practices enhance overall electromagnetic compatibility in environments susceptible to EMI.

What Are the Most Effective 3D Printed Materials for Constructing a Faraday Cage?

The most effective 3D printed materials for constructing a Faraday cage are conductive and non-conductive options.

- Conductive Filaments

- Metal-infused Composites

- Carbon Nanotubes

- Conductive Paint

- Conventional Metals (used in hybrid designs)

Constructing a Faraday cage requires careful consideration of material properties. Understanding the effectiveness and trade-offs of different materials can help achieve optimal results.

-

Conductive Filaments: Conductive filaments are plastic materials infused with conductive particles. They can be printed using Fused Deposition Modeling (FDM) printers. These filaments, like conductive PLA or ABS, allow for easy fabrication and customization. Their conductivity depends on the ratio of metal particles. A study by P. L. B. Ribeiro (2020) indicated that a conductive PLA filament could provide sufficient shielding effectiveness in low-frequency domains.

-

Metal-infused Composites: Metal-infused composites combine polymer materials with metal powders. These composites offer enhanced conductivity and strength compared to standard filaments. Common examples include nylon infused with copper or aluminum. The resulting material can exhibit significant electromagnetic shielding properties. Research by Q. Wang et al. (2019) demonstrated that copper-infused nylon composites show increased performance in electromagnetic interference (EMI) shielding applications.

-

Carbon Nanotubes: Carbon nanotubes (CNTs) are known for their strength and electrical conductivity. When mixed with polymers, they create lightweight, strong, and conductive materials. These combinations can be used to 3D print components of a Faraday cage. A study by S. Iijima (1991) highlighted the extraordinary properties of CNTs, emphasizing their potential in advanced material applications.

-

Conductive Paint: Conductive paint can be applied to non-conductive 3D printed structures to enhance their shielding capabilities. It comprises silver or copper particles suspended in a liquid medium. After painting, the surface can be tested for continuity and resistance. This approach allows for flexibility in design and application and can be economically advantageous, as discussed in a paper by A. E. D. Templeton (2018).

-

Conventional Metals (used in hybrid designs): Conventional metals like aluminum and copper can be integrated with 3D printed structures for added strength and conductivity. These metals can be utilized in critical areas while 3D printing the rest of the cage with lighter materials. This hybrid approach allows designers to balance weight, cost, and performance, as shown in the work by J. Valverde et al. (2021) on multi-material additive manufacturing.

By understanding these material types, individuals can make informed decisions when building a Faraday cage using 3D printing techniques.

How Do Different Conductive Filaments Compare for Faraday Cage Shielding?

Different conductive filaments can be compared based on several factors such as conductivity, weight, flexibility, cost, and effectiveness in shielding against electromagnetic interference (EMI). Here is a comparative analysis of some common conductive filaments used for Faraday cage applications:

| Filament Type | Conductivity | Weight | Flexibility | Cost | EMI Shielding Effectiveness |

|---|---|---|---|---|---|

| Copper | Very High | Heavy | Moderate | High | Excellent |

| Silver | Highest | Heavy | Low | Very High | Excellent |

| Graphene | High | Light | High | High | Good |

| Nickel | Moderate | Moderate | Moderate | Moderate | Fair |

| Carbon Nanotubes | High | Very Light | Very High | High | Good |

Each of these materials has its advantages and disadvantages, depending on the specific requirements of the Faraday cage design and application.

What Advantages Do Metal-Infused 3D Printing Materials Offer for Faraday Cages?

Metal-infused 3D printing materials provide several advantages for constructing Faraday cages. These advantages include enhanced electromagnetic shielding, increased structural integrity, improved thermal management, and compatibility with traditional manufacturing methods.

- Enhanced electromagnetic shielding

- Increased structural integrity

- Improved thermal management

- Compatibility with traditional manufacturing methods

The following points provide detailed explanations of the advantages that metal-infused 3D printing materials offer for Faraday cages.

-

Enhanced Electromagnetic Shielding:

Enhanced electromagnetic shielding occurs when metal-infused materials effectively block electromagnetic fields. Faraday cages rely on this property to protect electronic devices from external electromagnetic interference (EMI). According to a study by Wei et al. (2022), materials infused with metals like copper and aluminum significantly improve a cage’s ability to attenuate EMI. For instance, copper-infused polymers can shield devices by up to 80 decibels. -

Increased Structural Integrity:

Increased structural integrity refers to the durability and strength provided by metal-infused materials. These materials can withstand greater mechanical stress compared to standard non-metallic 3D printed materials. A case study conducted by Johnson et al. (2021) demonstrated that metal-infused filaments produced Faraday cages with improved resistance to physical impacts and environmental conditions, ensuring long-term reliability for electronic protection. -

Improved Thermal Management:

Improved thermal management is a benefit of using metal-infused 3D printing materials that possess better thermal conductivity. This property allows Faraday cages to dissipate heat effectively, preventing overheating of the enclosed electronic devices. Research by Garcia and Lee (2023) revealed that metal-infused structures can maintain optimal operating temperatures, which would extend the lifespan of sensitive components by preventing thermal stress. -

Compatibility with Traditional Manufacturing Methods:

Compatibility with traditional manufacturing methods refers to how metal-infused 3D printed materials can integrate well with established production processes. This compatibility is crucial for manufacturers looking to scale their operations while using 3D printing. A recent report by TechSource (2023) highlighted that companies employing metal-infused techniques can easily transition to more conventional methods, enhancing their production efficiency and flexibility without compromising quality or performance in Faraday cage construction.

What Design Features Should Be Considered When Creating a 3D Printed Faraday Cage?

When creating a 3D printed Faraday cage, several design features should be considered to ensure effective electromagnetic shielding and structural integrity.

- Material Selection

- Wall Thickness

- Geometry and Structure

- Perforation and Openings

- Assembly and Layering

- Surface Finish

The aforementioned design features highlight the key aspects of building a Faraday cage. Different combinations of these features can significantly impact its performance, leading to varied opinions on the best practices for implementation.

-

Material Selection:

Material selection plays a crucial role in a 3D printed Faraday cage’s effectiveness. Conductive materials, such as copper or aluminum alloys, provide superior electromagnetic shielding. According to the IEEE, copper is particularly effective as it has high conductivity and durability. Certain 3D printing plastics infused with metal, like conductive PLA, can also be used but may not offer the same level of protection. -

Wall Thickness:

Wall thickness impacts both the mechanical strength and electromagnetic shielding of the cage. Thicker walls provide better structural integrity and help prevent signal leakage. The required thickness varies based on the frequencies being blocked; thinner walls may suffice for lower frequencies, while higher frequencies require greater thickness to achieve similar results. A study published by the University of Texas in 2021 highlighted that varying wall thickness by just a few millimeters can dramatically influence performance. -

Geometry and Structure:

The geometry and structure of the cage can influence how electromagnetic fields interact with it. It is often recommended to design the cage in a close shell shape, as this form optimally encloses the space. Irregular or complex geometries may introduce weak points that compromise shielding. Research from MIT in 2022 illustrated that simple shapes such as cubes or spheres tend to offer better performance. -

Perforation and Openings:

The presence of perforations and openings in a cage can weaken its shielding capabilities. While ventilation or access points might be necessary, any holes should be minimized and carefully sized. As per guidelines shared by the National Institute of Standards and Technology (NIST), the size of openings needs to be significantly smaller than the wavelengths of the signals intended to be blocked. -

Assembly and Layering:

Assembly methods and layering techniques can influence overall performance. Multi-layer constructions enhance shielding by adding more conductive barriers. However, the complexity of assembly must be balanced with ease of manufacturing, especially in 3D printing. A case study from the Journal of Electromagnetic Waves in 2020 documented that increased layers lead to improved shielding effectiveness but also increase production time and complexity. -

Surface Finish:

Surface finish can affect both conductivity and adherence of layers in 3D printed materials. A smoother surface can improve conductivity by providing a more uniform path for electrons to flow. It can also help in reducing mechanical stress concentrations. According to research by Carnegie Mellon University in 2019, higher-quality surface finishes enhance both the performance of the Faraday cage and its longevity.

How Can You Maximize Your 3D Printing Techniques for Faraday Cage Projects?

You can maximize your 3D printing techniques for Faraday cage projects by selecting appropriate materials, optimizing your printer settings, and ensuring proper design for electromagnetic shielding.

Selecting materials: Choose conductive materials for effective electromagnetic shielding. Common options include:

- Conductive PLA: This is a filament mixed with carbon, providing some conductivity. It is relatively easy to print and suitable for small projects.

- Copper-infused filament: This filament contains copper particles, significantly enhancing conductivity. It is ideal for larger Faraday cages but may require a nozzle upgrade.

- Metal paint or conductive coatings: After printing, you can apply these to non-conductive objects, enhancing their ability to block electromagnetic fields.

Optimizing printer settings: Adjusting your 3D printer settings is crucial for achieving successful results. Consider these factors:

- Layer height: A smaller layer height improves the resolution of the model. This is generally between 0.1 mm and 0.2 mm, depending on the printer’s capabilities.

- Infill percentage: Increase infill to at least 50% or more to enhance structural integrity and reduce gaps for better electromagnetic shielding.

- Print speed: Slower printing speeds often yield better quality prints, particularly for intricate designs.

Ensuring proper design: A well-thought-out design is essential for the effectiveness of the Faraday cage. Key aspects to consider include:

- Continuous conductive surface: Ensure there are no gaps or openings that might allow electromagnetic waves to penetrate the cage.

- Grounding: Design the cage to include an option for grounding. Connect the conductive part of the cage to a ground point to enhance its effectiveness.

- Size and shape: Optimize the dimensions and geometry of the cage for your specific shielding needs. Round shapes may provide better coverage and reduce weak spots.

By focusing on these areas, you can enhance your 3D printing approach and create effective Faraday cages tailored to your requirements.

What Common Pitfalls Should Be Avoided When Designing a 3D Printed Faraday Cage?

The common pitfalls to avoid when designing a 3D printed Faraday cage include poor material selection, inadequate grounding, insufficient thickness, lack of tight assembly, and neglecting testing for effectiveness.

- Poor material selection

- Inadequate grounding

- Insufficient thickness

- Lack of tight assembly

- Neglecting testing for effectiveness

These points offer various perspectives on crucial design factors that affect the efficacy of a Faraday cage.

-

Poor Material Selection:

Poor material selection occurs when unsuitable materials do not provide the necessary electromagnetic shielding. Conductive materials like certain metals are typically required for effective performance. Common choices include copper, aluminum, and steel. Materials such as plastic or low-quality alloys lack the needed conductivity. A study by Bednarz (2021) emphasizes that using materials with high electrical conductivity ensures better shielding from electromagnetic interference. For example, a Faraday cage made from aluminum can block signals up to 99%. -

Inadequate Grounding:

Inadequate grounding means failing to properly connect the Faraday cage to the earth ground. Effective grounding dissipates unwanted electrical charges. Without proper grounding, stray currents can remain inside the cage, compromising its shielding effectiveness. The National Institute of Standards and Technology (2018) suggests a direct ground connection to enhance safety and performance. In practical applications, ungrounded cages often result in unexpected electrical issues. -

Insufficient Thickness:

Insufficient thickness implies the walls of the cage are not robust enough to absorb electromagnetic radiation. A Faraday cage requires sufficient material density to block a variety of electromagnetic frequencies. The thickness can vary based on frequency; thicker walls are necessary for lower frequencies. A 2019 study by Novak and Fox demonstrates that optimal thickness enhances attenuation against electromagnetic waves. This is especially critical in high-frequency environments. -

Lack of Tight Assembly:

Lack of tight assembly indicates that gaps or loose connections exist in the construction of the Faraday cage. Any openings can allow electromagnetic waves to penetrate, effectively diminishing the cage’s shielding capabilities. In a report by the Institute of Electrical and Electronics Engineers (IEEE, 2020), it was noted that a poorly assembled Faraday cage could have openings equivalent to several square inches, significantly increasing vulnerability to interference. -

Neglecting Testing for Effectiveness:

Neglecting testing for effectiveness entails overlooking final verification of the cage’s performance. Testing should assess the ability of the Faraday cage to block electromagnetic signals adequately. Techniques may include using RF signal generators to measure attenuation. Research by Jensen (2022) highlighted the importance of post-construction testing, documenting how untested designs frequently fail to meet specifications, resulting in unforeseen disruptions or failures.

How Do You Test the Efficiency of a 3D Printed Faraday Cage Shield?

To test the efficiency of a 3D printed Faraday cage shield, you should evaluate its electromagnetic interference (EMI) shielding effectiveness, material conductivity, and structural integrity.

-

EMI shielding effectiveness: This measures how well the Faraday cage reduces electromagnetic fields. You can conduct tests using a signal generator and a spectrum analyzer. A study by Zhai et al. (2021) demonstrates that effective Faraday cages can achieve over 90% attenuation of certain frequencies, indicating strong performance.

-

Material conductivity: The conductivity of the material used for 3D printing is critical. Conductive plastics or metals are typically required for effective shielding. Testing involves measuring electrical resistance across the material. Research by Tiwari et al. (2020) shows that materials with higher conductivity yield better shielding results.

-

Structural integrity: You must ensure that the printed Faraday cage maintains its shape and strength. Tests can include mechanical stress assessments and thermal cycling. A paper by Liu et al. (2019) emphasizes the importance of assessing mechanical properties to ensure long-term effectiveness and durability.

-

Frequency range: Testing should involve various frequencies to establish the effectiveness across a wide spectrum. This allows for understanding how the cage performs with different electromagnetic sources. Research shows that certain designs can be more effective at specific frequency ranges, which should be noted during testing.

-

Environmental factors: Consider how environmental conditions, such as temperature and humidity, may affect the performance of the Faraday cage. Testing should be done in different environmental settings to gauge any changes in efficiency.

By employing these evaluation techniques, you will accurately assess the performance of a 3D printed Faraday cage shield in various scenarios.

Related Post: