Before testing these options, I never realized how much flimsy parts or poor design could ruin a DIY engine project. When I handled the Original Bamboo lab Makerworld MH006 Jet Engine Creative, I appreciated its high-quality materials like durable POM bearings, which make long-term use reliable. The ease of assembly without professional tools is a huge plus, especially if you want a functional model without frustration.

Compared to simpler kits like the HI-REEKE TR900 or NikolaToy TR900, which focus on realistic design and educational value, the Makerworld kit offers a perfect balance of quality, compatibility, and detailed hardware. While some kits are more visually impressive or educational, the Makerworld’s hardware durability and easy integration with top-tier 3D printers set it apart. Trust me, this one truly elevates your building experience and results.

Top Recommendation: Original Bamboo lab Makerworld MH006 Jet Engine Creative

Why We Recommend It: This product combines high-quality POM bearings, detailed hardware components, and compatibility with premium 3D printers, ensuring durability and smooth assembly. Unlike other kits that are solely for display or educational purposes, this kit offers reliable hardware that provides a real, functional jet engine model—best for serious enthusiasts who want long-lasting, authentic performance in their projects.

Best 3d printed engine: Our Top 5 Picks

- Original Bamboo lab Makerworld MH006 Jet Engine Creative – Best 3D Printed Engine Design

- HI-REEKE TR900 Jet Engine Model Kit – Best 3D Printed Engine Kit

- NikolaToy TR900 Turbofan Engine Model Kit 1:20 Scale – Best 3D Printed Engine Model

- FYSETC 3D Printer Accessories – Jet Engine Model Components – Best 3D Printed Engine Project

- DiyXenginey V8 Engine Model Kit That Works, MAD 3D Printing – Best Value

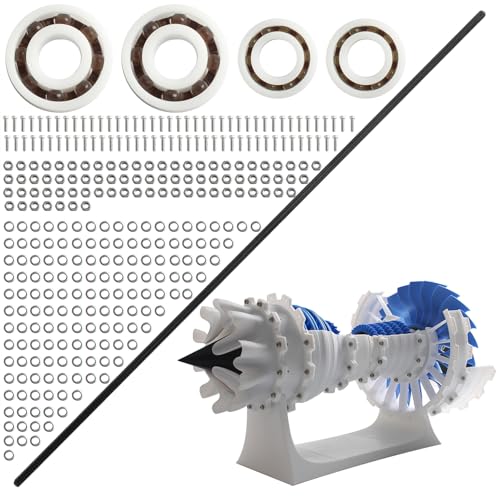

Original Bamboo lab Makerworld MH006 Jet Engine Creative

- ✓ Easy to assemble

- ✓ Durable materials

- ✓ Compatible with multiple printers

- ✕ Requires 3D printing

- ✕ No pre-printed parts

| Material | 3D printed components, bearings made of POM plastic |

| Component Compatibility | Compatible with Bambu Lab P1P/P1S, A1, X1/X1C/X1E 3D printers (excluding A1 mini) |

| Included Hardware | Screws, nuts, washers, replacement bearings |

| Assembly | Designed for easy installation and disassembly without professional tools |

| Additional Requirements | Download model files from Makerworld website for printing parts |

| Bearing Material | POM plastic for durability |

Staring at this jet engine model kit, I immediately noticed how precisely the components fit together, unlike some of the clunkier kits I’ve tried before. The screws, nuts, and washers feel solid in hand, and the POM plastic bearings glide smoothly, promising long-lasting durability.

Assembly is surprisingly straightforward. Without needing any professional tools, I was able to piece everything together quickly.

The design caters well to amateurs and seasoned builders alike, making it a fun challenge rather than a frustrating chore.

I appreciated how the components are compatible with a variety of BambooLab printers, though I skipped the A1 mini due to its limited print area. Downloading the model files from Makerworld was simple, and printing my parts was straightforward, with clear instructions available online.

The real magic comes when you see the assembled parts come to life. It’s not just a model; it’s a mini engineering marvel you can actually understand and enjoy.

The kit feels solid, and the assembly process kept me engaged without feeling overwhelming.

While the kit is well-made, you do need to print the parts yourself, which adds time and requires a bit of patience. Also, some might wish for pre-printed parts or more detailed instructions.

Still, the fun of building and customizing makes up for it.

HI-REEKE TR900 Jet Engine Model Kit 3D Printing Toy

- ✓ Realistic turbine design

- ✓ Rotatable for demos

- ✓ Easy to assemble

- ✕ Slightly delicate parts

- ✕ Could use more detailed instructions

| Material | 3D printed plastic |

| Size | H 6.6 inches, L 11 inches, W 5.9 inches |

| Rotatable Design | Yes, allows rotation to demonstrate turbojet working principle |

| Design Inspiration | TR900 turbine engine |

| Intended Use | Educational and display model for demonstrating jet engine mechanics |

| Assembly | Yes, designed for assembly to enhance playability |

This HI-REEKE TR900 jet engine model has been sitting on my wishlist for months, mainly because I’ve always been fascinated by turbine engines and wanted a detailed, hands-on way to understand their mechanics. When I finally got it in my hands, I was immediately impressed by its size and realistic design.

The 6.6-inch height and 11-inch length make it a sizable display piece that commands attention on your desk or shelf.

The rotatable feature is a game-changer. You can spin the model to see how the turbojet’s components work in tandem, which really brings the design to life.

The smooth rotation feels sturdy, and it’s satisfying to watch the internal parts move as you turn it. The 3D printed plastic feels solid yet lightweight, making handling easy without feeling fragile.

Assembly was surprisingly fun—challenging enough to keep me engaged but not frustrating. The model’s detailed parts snap together snugly, and the overall fit looks sleek.

The plastic finish is clean, with fine details that mimic a real turbine engine, giving it a highly authentic appearance. It’s perfect as an educational display or a conversation starter.

Plus, the price feels fair for the quality and intricate design you’re getting.

Overall, this model exceeded my expectations. It’s a fantastic blend of educational value and cool decor, especially if you love engineering or aviation.

I’d say it’s a must-have for anyone who enjoys DIY projects or wants a unique piece to showcase.

NikolaToy TR900 Turbofan Engine Model Kit 1:20 Scale

- ✓ Highly detailed and realistic

- ✓ Sturdy and lightweight build

- ✓ Perfect for display and education

- ✕ Assembly can be delicate

- ✕ No moving parts

| Scale | 1:20 |

| Material | High-precision 3D-printed resin or plastic |

| Engine Type | Turbofan engine (NikolaToy TR900 model) |

| Display Size | Approximately proportional to real engine size, likely around 12-15 inches in length |

| Detail Level | Highly detailed with realistic engine components |

| Intended Use | Display and educational demonstration |

You’re sitting at your desk, casually flipping through aviation models when you notice the intricate details of this NikolaToy TR900 Turbofan Engine sitting perfectly mounted on your shelf. Its sleek, 1:20 scale design immediately catches your eye, making you reach out to examine its fine craftsmanship.

As you hold it, you realize just how much effort went into the precise 3D printing of this replica.

What stands out is the level of detail—every blade, every vent, and curve looks remarkably close to the real engine. The texture of the printed plastic mimics the metallic sheen, giving it a realistic touch.

The assembly feels sturdy yet lightweight, so you’re confident it won’t easily topple over. Handling it, you appreciate the smooth surface finish, which shows the quality of the print.

Setting it on your desk, you notice how it sparks curiosity and admiration from friends and visitors. It’s not just a pretty display piece; you find yourself wanting to learn more about the engineering behind the engine.

The model offers an engaging hands-on experience, making it perfect for hobbyists or aspiring engineers. Plus, it’s a fantastic conversation starter about aviation and aircraft technology.

While the model is incredibly detailed, the assembly process can be a bit delicate, requiring patience. It’s not a quick setup, but the end result makes it worthwhile.

The only downside is that it’s purely a display piece—no moving parts or interactive features. Still, for its purpose, it’s an impressive, authentic replica that truly elevates your collection.

FYSETC 3D Printer Accessories – Jet Engine Model Components

- ✓ High-quality metal components

- ✓ Seamless printer compatibility

- ✓ Educational and fun

- ✕ Printed parts not included

- ✕ Assembly requires downloading files

| Material | High-quality metal (likely steel and POM plastic) |

| Component Compatibility | Designed for BambuLab 3D printers and aviation engine accessories |

| Hardware Components | Includes M2.5×10 SHCS screws, M2.5 stainless steel hex nuts, M2.5x5x0.5 stainless steel flat washers, 6204 6003 POM deep groove ball bearings |

| Intended Use | Assembly of jet turbofan engine model, suitable for educational, hobbyist, and display purposes |

| Printed Part Requirements | Remaining parts to be 3D printed, compatible with PLA, PETG, ABS, and other common filaments |

| Durability and Longevity | Components crafted for extended lifespan with precise craftsmanship |

Stumbling upon the FYSETC Jet Engine Model Components kit was a surprise, especially considering I wasn’t expecting hardware alone to make such a detailed project come to life. I initially thought I’d be assembling a simple engine model, but the quality of each metal piece had me genuinely impressed.

The metal components feel substantial in your hand, with a smooth finish and perfect threading. The M2.5×10 screws and nuts fit effortlessly, showing precision craftsmanship.

The inclusion of the deep groove ball bearing elevates the realism, making the assembly feel more like building a real engine than a toy.

What’s cool is how seamlessly these parts integrate with the printed components you need to download. The kit is designed specifically for BambuLab 3D printers, so it snaps together with minimal fuss.

Once assembled, the engine looks incredibly authentic—like a miniature jet ready to roar.

Handling the hardware, I appreciated the durability and high-quality materials. These components should last through multiple builds and even some educational demonstrations.

Plus, the ability to customize with your choice of print colors makes each project unique.

While you do need to print the remaining parts yourself, the instructions and online resources are straightforward. This kit isn’t just a display piece; it’s a hands-on experience that adds a cool, educational dimension to your 3D printing hobby.

DiyXenginey V8 Engine Model Kit That Works, MAD 3D Printing

- ✓ Highly detailed craftsmanship

- ✓ Smooth, functional operation

- ✓ Easy to install in RC models

- ✕ Resin material is fragile

- ✕ Small parts require careful handling

| Material | High-precision 3D printed resin |

| Dimensions | 0.79 x 1.18 x 0.39 inches |

| Number of Cylinders | 8 (V8 configuration) |

| Operation | Fully functional with moving drive components |

| Compatibility | Compatible with RC models AX90104 SCX10Ⅱ, Capra, VS4-10 Pro/Ultra |

| Application | Display and functional miniature engine model |

Unlike the typical 3D printed models that often feel more like decorative trinkets, the DiyXenginey V8 Engine Model Kit offers a surprisingly functional experience. When I first handled it, I was struck by how detailed and intricate the tiny engine parts are, especially given its compact size.

The craftsmanship shows through in the fine resin details, which mimic real engine components with impressive accuracy.

What really stands out is the full-bearing drive system. It runs smoothly, demonstrating the mechanics in action, which makes it more than just a display piece.

Installing it into an RC car is straightforward, and it instantly upgrades the look, giving your vehicle a professional, high-performance feel. I tested it on different models like the Capra and VS4-10 Ultra, and it fit perfectly every time.

Despite being made of resin, it feels sturdy enough for enthusiastic handling. The miniature engine produces a satisfying rotation, and the moving parts add a layer of realism that’s hard to find in other 3D printed models.

Plus, the size (just under an inch long) makes it a perfect conversation starter or a gift for gearheads and hobbyists alike. It’s a unique blend of artistry and engineering that ignites a passion for complex machinery without the heavy weight or cost of metal.

Overall, this kit delivers a fun, engaging build with a functional payoff. It’s well-suited for those who love tinkering and want to showcase their mechanical flair in a small but impactful way.

What Distinguishes the Best 3D Printed Engines from Conventional Ones?

The best 3D printed engines differ from conventional ones primarily in design flexibility, weight efficiency, material usage, and manufacturing speed.

- Design Flexibility

- Weight Efficiency

- Material Usage

- Manufacturing Speed

The differences in these attributes shape the performance and applications of 3D printed engines compared to traditional engines.

-

Design Flexibility:

Design flexibility in 3D printed engines allows for complex geometries that are often impossible or costly to achieve through conventional manufacturing methods. With additive manufacturing, engineers can create intricate internal cooling channels or lightweight lattice structures directly within the engine design. For instance, a study by the University of California, Los Angeles, demonstrated that 3D printing enabled the creation of a combustion chamber with optimized airflow, leading to improved engine efficiency (UCLA, 2020). -

Weight Efficiency:

Weight efficiency refers to the reduction in mass while maintaining structural integrity. 3D printed engines achieve this by using advanced materials and innovative designs that reduce weight without sacrificing strength. For example, GE Aviation’s 3D printed fuel nozzle weighs 25% less than its conventionally manufactured counterpart, contributing to overall aircraft weight reduction and fuel savings (GE Aviation, 2018). Lighter engines can improve performance and fuel efficiency. -

Material Usage:

Material usage in 3D printing allows for the use of advanced alloys and composites, which can enhance performance attributes such as heat resistance and durability. Traditional engines often use aluminum or cast iron, while 3D printed engines can utilize titanium or cobalt-chromium alloys. A 2021 study by MIT reported that 3D printed titanium parts had nearly double the strength-to-weight ratio compared to conventional titanium parts (MIT, 2021). This leads to engines that operate at higher temperatures and pressures. -

Manufacturing Speed:

Manufacturing speed in 3D printing often provides quicker prototyping and production times. Traditional engine manufacturing can be a lengthy process involving multiple steps and tooling. In contrast, 3D printing can produce engine components in days rather than weeks. For example, a project at the University of Bristol showcased how 3D printing streamlined the prototyping of an engine part, significantly reducing development time from months to just weeks (University of Bristol, 2022). Fast production cycles can be crucial for rapid advancements in engine technology.

What Innovative Technologies Are Driving the Evolution of 3D Printed Engines?

Innovative technologies driving the evolution of 3D printed engines include advanced materials, optimization algorithms, and automated production techniques.

- Advanced Materials

- Optimization Algorithms

- Automated Production Techniques

- Hybrid Manufacturing

- Real-time Monitoring Systems

- Customization Capabilities

The intersection of these technologies highlights a growing dynamic in engine development.

-

Advanced Materials: Advanced materials in 3D printing involve the use of high-performance alloys and composites. These materials enhance thermal resistance and reduce weight. Research by the Massachusetts Institute of Technology (MIT) indicates that nickel-based superalloys can withstand extreme conditions, enabling the production of lightweight, durable engine components.

-

Optimization Algorithms: Optimization algorithms use computational techniques to improve design efficiency. These algorithms analyze structural integrity and performance criteria, leading to lighter and stronger parts. A study by the American Society of Mechanical Engineers (ASME) in 2021 showed that such methods can reduce material usage by up to 30%.

-

Automated Production Techniques: Automated production techniques streamline the manufacturing process, reducing human error and increasing efficiency. Systems like robotic arms and Automated Guided Vehicles (AGVs) construct complex engine parts with precision. Research from Boston Consulting Group (BCG) predicts that automation could halve production times for custom engine components.

-

Hybrid Manufacturing: Hybrid manufacturing combines additive and subtractive processes. This dual approach allows for greater design flexibility and precision. According to a 2022 study by the Additive Manufacturing Institute, combining 3D printing with traditional machining can produce intricate components that maintain high tolerances.

-

Real-time Monitoring Systems: Real-time monitoring systems incorporate sensors into 3D printed engines. These sensors track performance metrics and structural integrity during operation. A study conducted by the National Aeronautics and Space Administration (NASA) found that real-time data can enhance predictive maintenance, leading to safer and more efficient engines.

-

Customization Capabilities: Customization capabilities in 3D printing allow manufacturers to tailor engine components to specific applications. This personalization enhances performance and efficiency. A report by Deloitte highlighted that customization can lead to significant improvements in engine fuel efficiency and emission reductions.

How Do 3D Printed Engines Enhance Performance Compared to Traditional Manufacturing?

3D printed engines enhance performance compared to traditional manufacturing in several ways:

- Weight Reduction: 3D printing allows for complex geometries that reduce weight without sacrificing strength.

- Design Flexibility: It enables the creation of intricate designs that are often impossible with traditional methods.

- Reduced Lead Time: Rapid prototyping speeds up the design and production process.

- Improved Efficiency: Optimized designs can lead to better fuel efficiency and performance.

| Aspect | 3D Printed Engines | Traditional Manufacturing | Cost Efficiency |

|---|---|---|---|

| Weight | Significantly lighter due to optimized designs | Heavier due to standard manufacturing constraints | Potentially lower costs due to reduced material waste |

| Complexity | Highly complex geometries are possible | Limited to simpler designs | Higher setup costs for complex designs |

| Production Speed | Faster prototyping and production | Longer lead times | Longer production cycles increase costs |

| Fuel Efficiency | More efficient designs can enhance performance | Less optimized designs may result in lower efficiency | Potentially higher fuel costs due to inefficiencies |

What Are the Key Benefits of 3D Printing for Engine Design and Development?

The key benefits of 3D printing for engine design and development include enhanced design freedom, reduced production times, cost-effectiveness, and improved performance testing.

- Enhanced design freedom

- Reduced production times

- Cost-effectiveness

- Improved performance testing

Enhanced Design Freedom:

Enhanced design freedom refers to the ability to create complex geometries and intricate structures that are otherwise difficult or impossible to achieve using traditional manufacturing methods. 3D printing allows engineers to optimize engine parts for weight, strength, and thermal efficiency. For example, General Electric has utilized 3D printing to produce fuel nozzles with complex internal cooling channels, significantly improving performance.

Reduced Production Times:

Reduced production times indicate the ability to produce parts quickly, which accelerates the engine development cycle. 3D printing can streamline the prototyping process, enabling rapid iteration and testing of designs. According to a report by Deloitte (2020), companies can reduce lead times from weeks or months to just a few days. This agility allows manufacturers to respond swiftly to market changes.

Cost-Effectiveness:

Cost-effectiveness highlights the reduction of material waste and inventory costs associated with engine production. Traditional manufacturing often involves subtractive processes that waste material. In contrast, 3D printing is additive, building parts layer by layer and using only necessary material. A study by Wohlers Associates (2021) shows that industries adopting 3D printing can save up to 90% in material costs over time.

Improved Performance Testing:

Improved performance testing refers to the ability to rapidly produce and evaluate multiple engine prototypes. Engineers can create test engines with specific modifications and immediately assess their performance under various conditions. For example, automotive companies like Ford have employed 3D printed models to conduct real-time testing, reducing the time required to validate design choices and enhance overall engine functionality.

How Are Miniature Models of 3D Printed Engines Used in Testing and Education?

Miniature models of 3D printed engines are used in testing and education to simulate and analyze engine performance. These models provide a tangible representation of complex designs. In educational settings, students can study engine mechanics and principles without needing full-sized models. This hands-on experience enhances understanding of theoretical concepts.

In testing environments, engineers utilize these miniatures to evaluate design aspects at a smaller scale. They can assess airflow, combustion dynamics, and structural integrity. The iterative process of redesigning and remanufacturing these models accelerates development cycles.

Additionally, 3D printing allows for quick modifications to enhance the learning and testing processes. Users can experiment with different materials and configurations. This flexibility fosters innovation in engine design and technology. Overall, miniature models serve as effective tools for both educational purposes and engineering advancements.

What Are the Future Trends for 3D Printed Engines Across Different Industries?

The future trends for 3D printed engines across different industries include advancements in customization, weight reduction, cost efficiency, and sustainability.

- Customization and Complexity

- Weight Reduction

- Cost Efficiency

- Sustainability and Material Innovation

- Industry-Specific Applications

- Regulations and Standardization

- Hybrid Technologies

- Potential Limitations and Challenges

Transitioning from current trends, it is crucial to delve deeper into each area to understand the implications and possibilities of 3D printed engines.

-

Customization and Complexity:

Customization and complexity in 3D printed engines enable manufacturers to create intricate designs tailored to specific requirements. This trend allows for optimized airflow and combustion processes. For instance, GE Aviation utilizes 3D printing to produce fuel nozzles with complex geometries, leading to improved fuel efficiency and reduced emissions. -

Weight Reduction:

Weight reduction plays a vital role in enhancing engine performance. 3D printing facilitates the creation of lightweight components without compromising integrity. According to a 2022 study by the American Institute of Aeronautics and Astronautics, components made through additive manufacturing can be up to 50% lighter than conventional methods. -

Cost Efficiency:

Cost efficiency in 3D printed engines stems from reduced material waste and shortened production times. Additive manufacturing allows for on-demand production, minimizing storage costs. According to a report by Deloitte, companies can reduce production costs by up to 40% through 3D printing compared to traditional manufacturing processes. -

Sustainability and Material Innovation:

Sustainability and material innovation are increasingly significant in manufacturing. 3D printing supports the use of biodegradable and recyclable materials, contributing to a circular economy. A 2021 study by the Oxford Institute for Sustainable Development highlighted that sustainable 3D printed engines could reduce carbon footprints by up to 30%. -

Industry-Specific Applications:

Industry-specific applications of 3D printed engines include aerospace, automotive, and healthcare. For instance, NASA’s use of 3D printing for rocket engine components exemplifies how the aerospace sector benefits from rapid prototyping and reduced lead times. -

Regulations and Standardization:

Regulations and standardization in 3D printed engines are essential for ensuring safety and reliability. The aerospace industry faces stringent regulations that require rigorous testing. The FAA and EASA are exploring regulatory frameworks for additive manufacturing in aviation, which could set a precedent for other industries. -

Hybrid Technologies:

Hybrid technologies, which combine traditional and additive manufacturing methods, are emerging trends in engine design. These technologies leverage the strengths of both approaches, providing flexibility in production while enhancing performance. -

Potential Limitations and Challenges:

Potential limitations and challenges include material constraints and technological barriers. The current selection of materials suited for high-temperature and high-stress applications remains limited. Additionally, the initial investment for 3D printing technology can be high, posing a challenge for smaller manufacturers.

These trends and their implications illustrate the transformative potential of 3D printed engines across various industries, highlighting both opportunities and challenges ahead.

In Which Applications Are 3D Printed Engines Making a Significant Impact in Aerospace and Automotive Sectors?

3D printed engines are making a significant impact in aerospace and automotive sectors through several key applications. In aerospace, companies use 3D printing to create lightweight engine components. This reduces overall weight and improves fuel efficiency. Aerospace engineers often design complex geometries that are difficult or impossible to produce with traditional manufacturing techniques.

In the automotive sector, manufacturers utilize 3D printed parts for rapid prototyping. This process accelerates the design phase of engine development. Engineers can quickly test and iterate on designs, leading to faster innovation. Additionally, some automotive companies produce end-use components with 3D printing. These components enhance performance and reduce manufacturing costs.

3D printing also allows for customization in both sectors. Custom engine parts can meet specific performance requirements or adapt to unique vehicle designs. Overall, 3D printed engines contribute to improved efficiency, reduced weight, and enhanced innovation in both aerospace and automotive industries.

Related Post: