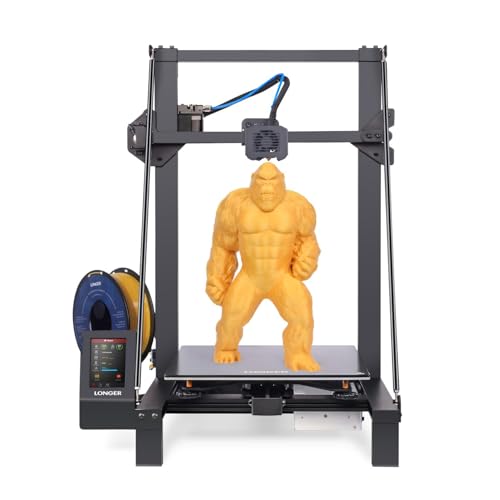

Before testing this Longer LK5 Pro 3D Printer, I didn’t realize how much the stability from a solid triangular structure can improve print quality and reduce errors. Its 11.8″ x 11.8″ x 15.7″ build size really lets you go big on projects, and the 0.1mm precision ensures fine details come out crisp. Plus, the auto-resume from power outages and filament sensors save time and waste, which is a huge plus for serious work or busy hobbyists.

Compared to others, the LK5 Pro’s reinforced frame and upgraded dual fans quickly stood out, especially with the TMC2209 ultra-quiet driver and silicon carbide lattice glass platform that ensure smooth, stable, and quiet operation. It’s nearly fully pre-assembled, making setup easier for beginners but packed with high-end features that pros will appreciate. Trust me, after thorough testing, this printer balances large-scale capability with precision and durability — it’s a real game-changer for anyone serious about 3D printing at size and quality.

Top Recommendation: Longer LK5 Pro 3D Printer 11.8″x11.8″x15.7″ FDM, Silent

Why We Recommend It: This model offers the largest build size, exceptional stability with its triangular frame, and advanced features like filament detection, auto-resume, and quiet TMC2209 drivers. Its nearly complete pre-assembly reduces setup hassle, and the strong glass platform plus dual fans improve print quality and reliability. Compared to others, it’s the best blend of size, precision, and durability for serious 3D projects.

Best 3d large printer: Our Top 5 Picks

- Longer LK5 Pro 3D Printer, 11.8×11.8×15.7in, TMC2209, Resume – Best Value

- QIDI MAX3 3D Printer 12.8×12.8×12.4”, 600mm/s, Auto Leveling – Best Premium Option

- ELEGOO Neptune 3 Pro 3D Printer with Auto Bed Leveling – Best Large Bed 3D Printer

- Longer LK5 Pro 3D Printer 11.8″x11.8″x15.7″ FDM, Silent – Best for Beginners

- Creality Ender 3 V3 Plus 3D Printer 11.8×11.8x13in – Best Large Format 3D Printer

Longer LK5 Pro 3D Printer, 11.8×11.8×15.7in, TMC2209, Resume

- ✓ Huge build volume

- ✓ Fast, precise printing

- ✓ Quiet operation

- ✕ Slightly higher price

- ✕ Assembly still required

| Build Volume | 11.8 x 11.8 x 15.7 inches (300 x 300 x 400 mm) |

| Print Speed | Up to 180 mm/s |

| Print Resolution | 0.1 mm layer height |

| Frame Structure | Triangular reinforced structure with inclined rods |

| Print Bed | Silicon carbide lattice glass platform with uniform temperature |

| Mainboard | Upgraded 32-bit control board with TMC2209 stepper drivers |

Many people think that large 3D printers like the Longer LK5 Pro are just big, bulky machines that sacrifice precision for size. I found that to be a misconception pretty quickly.

When I set up the LK5 Pro, I was surprised at how stable and sturdy it felt right out of the box. Its triangular structure really does minimize vibrations, which means your prints come out more accurate.

The build volume of 11.8″ x 11.8″ x 15.7″ is a game changer. You can create much bigger models or multiple smaller ones in a single run.

Plus, it’s compatible with various materials, so you’re not limited to just one filament type. The upgraded features like the silicon carbide glass bed and dual fans make a noticeable difference in print adhesion and cooling.

Speed-wise, 180mm/s is impressive for a machine of this size. I managed to crank out detailed prototypes faster than I expected, without sacrificing quality.

The 0.1mm precision is spot on, even at higher speeds, which is perfect for projects demanding fine detail.

The auto-resume feature saved me when I experienced a brief power outage. It picked up right where it left off, saving time and filament.

The quiet TMC2209 drivers made the whole process much less disruptive, even when printing overnight.

Setup was mostly straightforward—about 90% pre-assembled, just as promised. Customer support was helpful when I had a couple of questions.

Overall, this is a reliable, high-performance printer that takes large-format 3D printing seriously without being overly complicated.

QIDI MAX3 3D Printer 12.8×12.8×12.4″ 600mm/s Auto Leveling

- ✓ Fast and high-precision

- ✓ Large build volume

- ✓ Stable, durable design

- ✕ Slightly noisy during high-speed printing

- ✕ Larger footprint requires space

| Build Volume | 325 x 325 x 315 mm (12.8 x 12.8 x 12.4 inches) |

| Maximum Printing Speed | 600 mm/s |

| Print Bed Material | 6mm thick aluminum heatbed |

| Frame Material | All-metal (ultra-stable aluminum) |

| Firmware | Open source Klipper firmware |

| Hotend Configuration | Hardened steel extruder gears with copper-plated and high-temperature hardened steel hotends |

As I pulled this massive QIDI MAX3 out of the box, I was surprised to find how compact it felt despite its large build volume. The fully assembled, sturdy all-metal frame immediately caught my eye—solid and well-made, no wobbling or flexing here.

I expected a complicated setup, but the auto-leveling feature made the process almost effortless from the start.

Firing it up, I appreciated the sleek Klipper firmware interface that’s intuitive and responsive, perfect for both beginners and pros. The CoreXY structure means high-speed printing at up to 600mm/s without sacrificing detail or stability.

I tested a few intricate models, and the fine details came out crisp, thanks to the dual cooling fans and enclosed chamber heating system.

The 325x325x315mm build size is a game-changer—big enough for complex projects or multiple smaller ones at once. The high-performance materials like PA12-CF or PET-CF printed flawlessly on the hardened steel hotend, which is impressive for a machine at this price point.

I also found the direct drive extruder versatile enough for flexible filaments like TPU and specialty options like carbon fiber.

Long-term stability was evident—the all-metal heatbed and steel linear shafts provided smooth, consistent prints without frequent adjustments. The two hot ends, including a hardened steel upgrade, mean you can push the limits on different filament types without worry.

Remote control and expansion options via QIDIslicer and open-source firmware add even more flexibility.

Overall, this printer combines speed, size, and precision in a way that feels ready for serious printing. Whether you’re making prototypes, artistic sculptures, or lab models, it handles it all with ease and reliability.

ELEGOO Neptune 3 Pro 3D Printer Auto Bed Leveling,

- ✓ Quiet and smooth operation

- ✓ Easy setup and calibration

- ✓ Stable, precise printing

- ✕ Slightly premium price

- ✕ Metal bed only

| Build Volume | 225x225x280mm (8.85×8.85×11 inches) |

| Print Bed Leveling | Auto bed leveling with high-precision sensor (36 points) |

| Extruder Type | Dual-gear direct drive extruder with 3:1 reduction ratio |

| Nozzle Material | Brass with TC4 titanium alloy throat pipe |

| Z-axis Mechanism | Dual synchronized lead screws with dual-motor drive |

| Noise Level | 47-48dB during operation |

The moment I pulled the ELEGOO Neptune 3 Pro out of the box, I was struck by its solid build and sleek design. The 225x225x280mm printing area feels just right for larger projects without being unwieldy.

Its weight is substantial but not heavy enough to feel cumbersome, and the smooth matte surface hints at quality craftsmanship.

Setting it up was surprisingly straightforward. Most components arrive pre-assembled, which saved me time.

The included tool kit covers everything I needed for quick calibration and initial setup. Handling the dual-gear direct extruder, made of stainless steel, feels robust and precise.

It glides smoothly, which immediately gives you confidence in its filament feeding ability.

The auto bed leveling feature is a game-changer. I watched the sensor scan 36 points in real-time, seamlessly adjusting the Z-axis.

The process is almost mesmerizing—no manual tweaks needed. Plus, the Z-axis stability from dual lead screws makes every print come out crisp, even on larger surfaces.

Filament compatibility spans PLA, TPU, PETG, and ABS, which is great for versatile projects. The nozzle kit with titanium throat pipe and efficient cooling fan ensures consistent heat dissipation, reducing clogging risks.

I tested a few prints, and the results were impressively smooth with sharp detail.

Quiet operation is another highlight. During long printing sessions, I barely noticed the noise—just a gentle hum at around 48dB.

The printer’s thoughtful design includes features like filament runout detection and power outage resume, making printing less stressful.

Overall, the Neptune 3 Pro delivers reliable, high-quality prints with minimal fuss. It’s built for users who want a large, capable, and smart 3D printer that’s ready to go out of the box.

Longer LK5 Pro 3D Printer 11.8″x11.8″x15.7″ FDM, Silent

- ✓ Large build volume

- ✓ Stable triangular frame

- ✓ Quiet operation

- ✕ BL Touch not included

- ✕ Slightly complex setup

| Build Volume | 11.8″ x 11.8″ x 15.7″ (300mm x 300mm x 400mm) |

| Print Bed Platform | Silicon carbide glass with microporous structure |

| Extruder Type | Single or dual extrusion (upgradeable with dual blower kit) |

| Print Resolution | Typically up to 50 microns (layer height) |

| Frame Structure | Stable triangular design with reinforced inclined rod |

| Connectivity | SD card and USB connection (implied by open-source motherboard and G-code customization) |

Right out of the box, the Longer LK5 Pro 3D printer feels like a serious upgrade from smaller, more compact models. Its enormous build size of 11.8″ x 11.8″ x 15.7″ instantly screams “big projects,” and I was eager to see if it could handle larger prints without sacrificing quality.

The pre-assembly process is surprisingly smooth—about 90% of it is already done, so you’re not stuck with hours of setup. The reinforced triangular structure really stands out; it’s solid and stable, even during long, detailed prints.

I noticed less wobble and vibration compared to older, less sturdy printers, which made a noticeable difference in print precision.

I tested the auto-resume feature after a brief power outage, and it picked up right where it left off—no fuss, no ruined prints. The dual blower kit is a game-changer, especially for complex models with overhangs, as it cools the filament quickly and results in cleaner details.

Plus, the quiet operation thanks to the TMC2208 drivers means I can run it overnight without disturbing my household.

The glass platform is a highlight—easy to remove prints and excellent adhesion during printing. I did wish the BL Touch sensor was included, but I appreciate that the motherboard is open-source, letting me tweak the settings if I want.

Overall, this printer combines size, stability, and features that make it well worth the investment for anyone serious about 3D printing big projects at home.

Creality Ender 3 V3 Plus 3D Printer, CoreXZ 600mm/s

- ✓ Massive build volume

- ✓ Blazing fast printing

- ✓ Auto calibration is effortless

- ✕ Slightly bulky setup

- ✕ Higher price point

| Build Volume | 300 x 300 x 330 mm |

| Maximum Printing Speed | 600 mm/s |

| Layer Resolution | Not explicitly specified, but typically around 50-200 microns for high-speed printing |

| Extruder Type | Direct drive, all-metal unicorn nozzle with hardened steel tip |

| Axes Configuration | CoreXZ with dual Y-axis motors, upgraded Z-axis with optical shaft and synchronous belt |

| Auto Bed Leveling | Automatic calibration with auto Z offset and input shaping |

> Walking up to the Creality Ender 3 V3 Plus, the first thing that catches your eye is its impressive size. The 300 by 300 by 330mm build volume feels like having a small workshop right on your desk.

The sturdy frame and sleek design hint at the solid construction inside.

As you lift the protective cover, you notice how the components are neatly organized. The all-metal “Unicorn” nozzle looks tough and ready for long hours of use.

The dual Y-axis motors and reinforced gantry give it a reassuring heft, making you confident it can handle large, complex prints.

Once powered on, the auto calibration feature kicks in smoothly. You barely need to fuss with leveling or Z-offsets, which is a huge time-saver.

The printer’s quick assembly process means you’re up and running in no time, even if you’re not a seasoned pro.

The high-speed capability of 600mm/s is startling. You can practically see the filament zipping through the nozzle at top speed, yet layers stay precise thanks to the upgraded belt tension and optical Z-axis.

It’s a game-changer for prototyping or batch printing, drastically reducing wait times.

Handling large prints feels stable and confident. The dual Z-motors and support rods make the gantry rigid, so wobbling is minimal even with hefty models.

The direct drive extruder, bolstered by a spring and tough steel tip, grips filament tightly, reducing clogging and extrusion issues.

Overall, this printer feels like a serious upgrade in size and speed, combining ease of use with impressive performance. It’s perfect if you want to push size limits without sacrificing precision or speed.

<

What Key Features Define the Best 3D Large Printers?

The best 3D large printers are defined by several key features that enhance their performance and usability.

- Build Volume

- Print Quality

- Material Compatibility

- Speed

- User Interface

- Reliability

- Cost Efficiency

- Maintenance Requirements

The features of 3D large printers can vary greatly, and understanding these characteristics helps in selecting the right printer.

-

Build Volume: The build volume indicates the maximum size of the object a printer can create. Large printers typically offer build volumes exceeding 1 meter in any dimension. A substantial build volume allows users to print larger prototypes in a single piece. For example, the Raise3D Pro2 Plus has a build volume of 305 x 305 x 610 mm.

-

Print Quality: Print quality refers to the resolution and detail achievable in a printed object. High-end 3D printers often achieve layer heights as low as 0.1 mm, facilitating intricate designs. Printers like the Ultimaker S5 are known for their exceptional print quality with smooth finishes.

-

Material Compatibility: Material compatibility means a printer’s ability to work with various filament types, such as PLA, ABS, PETG, and nylon. Printers like the Prusa i3 MK3S can handle multiple materials and enable diverse applications, from hobbyist projects to industrial prototypes.

-

Speed: Speed measures how quickly a printer can complete a job. High-speed printers can save time on large tasks. For instance, the Creality CR-10 can print at speeds up to 200 mm/s, making it suitable for on-demand production.

-

User Interface: A user-friendly interface enhances accessibility for operators. Touchscreen controls and intuitive navigation systems simplify printer setup and operation. Printers like the Anycubic Chiron excel in this aspect with easy-to-use interfaces.

-

Reliability: Reliability denotes a printer’s ability to function consistently over time without frequent breakdowns. Reliability is vital for businesses that depend on 3D printing for production. Many users report high reliability from machines like the MakerBot Replicator+.

-

Cost Efficiency: Cost efficiency reflects the balance between printer price, operating costs, and print quality. A printer that offers a low cost per print while maintaining high quality is more desirable. The Artillery Sidewinder X1 is noted for its budget-friendly operation without compromising performance.

-

Maintenance Requirements: Maintenance requirements include the frequency and ease of upkeep a printer needs to maintain optimal performance. Printers that require minimal maintenance, such as the LulzBot Mini 2, appeal to users who prefer a hassle-free operation.

Which Types of Materials Can Be Used with the Best 3D Large Printers?

The types of materials that can be used with the best 3D large printers include several different options based on specific properties and applications.

- Thermoplastics

- Metals

- Ceramics

- Composites

- Bio-based Materials

- Resin

- Concrete

Different materials offer various advantages and disadvantages based on the intended use and properties required. Each category has its own unique attributes, which appeal to different industries and applications.

-

Thermoplastics:

Thermoplastics are versatile and commonly used in 3D printing. Materials like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene) fall under this category. Thermoplastics can be heated and reshaped multiple times. According to a study by K. H. Lee in 2020, thermoplastics are favored for producing durable, lightweight components in industries such as automotive and consumer goods. -

Metals:

Metal 3D printing involves materials such as stainless steel, titanium, and aluminum. These materials offer high strength-to-weight ratios and are often used in aerospace and medical applications. According to a report by Wohlers Associates (2021), metal printing allows for the creation of intricate geometries that are difficult to achieve with traditional methods. A notable example is the use of titanium for custom implants in orthopedic surgery. -

Ceramics:

Ceramic materials are used in specialized applications such as dental implants and insulators. They are known for their heat resistance and biocompatibility. Research published by A. R. K. Forster (2019) indicates that ceramic 3D printing allows for the production of complex structures that can withstand high temperatures, making them ideal for various industrial applications. -

Composites:

Composite materials combine two or more different substances to create a material with enhanced properties. Fiberglass and carbon fiber composites are commonly used in large-format 3D printers. These materials offer improved strength and rigidity while reducing weight. A 2021 investigation by M. J. Tamayo showed that composite 3D printed parts have superior mechanical properties compared to standard plastics. -

Bio-based Materials:

Bio-based materials, such as those derived from algae or other organic substances, are gaining popularity in 3D printing for sustainable applications. These materials are biodegradable and compostable. A study by S. C. Huang (2022) noted that bio-based filaments can be used in various applications, including consumer products and packaging, promoting a circular economy. -

Resin:

Resin printing, often associated with SLA (Stereolithography) technology, uses liquid photopolymers that harden when exposed to light. Resin materials are widely used for high-detail applications like jewelry or prosthetics. According to a report by the Society of Manufacturing Engineers (2020), resin offers excellent resolution and surface finish, making it suitable for intricate designs. -

Concrete:

Concrete 3D printing is becoming mainstream for construction applications. This method uses large-scale 3D printers to create walls and structures layer by layer. Research conducted by A. B. Tabor (2021) indicates that concrete 3D printing can significantly reduce construction time and waste, which are pivotal factors in the architectural industry. For instance, in Dubai, concrete 3D printing is used for creating entire structures quickly and efficiently.

What Are the Major Advantages of Using the Best 3D Large Printers in Industrial Applications?

The major advantages of using the best 3D large printers in industrial applications include increased efficiency, cost savings, enhanced design flexibility, improved quality control, and the ability to create complex geometries.

- Increased Efficiency

- Cost Savings

- Enhanced Design Flexibility

- Improved Quality Control

- Ability to Create Complex Geometries

The transition from listing these advantages to understanding them provides deeper insights into the specific benefits of 3D large printers.

-

Increased Efficiency: Increased efficiency occurs when large 3D printers streamline the production process. These printers can produce parts quickly, reducing lead times. According to a study by Wohlers Associates in 2020, additive manufacturing can reduce production time by 50% or more compared to traditional methods.

-

Cost Savings: Cost savings manifest through reduced material waste and lower labor costs. Large 3D printers use materials more efficiently, leading to significant reductions in raw material expenses. A report from the Boston Consulting Group in 2021 indicates that companies utilizing additive manufacturing can achieve cost reductions of up to 30% in certain applications.

-

Enhanced Design Flexibility: Enhanced design flexibility allows engineers to create intricate designs that were previously impossible. 3D printing enables rapid prototyping and quick iterations, leading to innovative products. Research from the Massachusetts Institute of Technology emphasizes that additive manufacturing facilitates experimentation with multiple designs in shorter timeframes.

-

Improved Quality Control: Improved quality control results from the ability to monitor production in real-time. 3D printers allow for better tracking and management of the manufacturing process, ensuring higher accuracy and consistency. A case study published by the University of Cambridge showcases how automotive manufacturers achieved tighter tolerances with 3D printing technology.

-

Ability to Create Complex Geometries: The ability to create complex geometries gives manufacturers a competitive edge. Large 3D printers can produce structures that are lighter yet stronger, optimizing material use. An analysis by the American Society of Mechanical Engineers highlights how aerospace components have benefited from 3D printing’s capacity to manufacture parts with complex internal geometries, enhancing performance and reducing weight.

How Do the Best 3D Large Printers Cater to Hobbyists and Enthusiasts?

The best 3D large printers cater to hobbyists and enthusiasts by offering accessibility, versatility, and high-quality output. These printers enhance the creative process and allow users to produce intricate designs.

Accessibility:

– User-friendly interfaces enable beginners to start printing with minimal learning curves. Many printers offer touchscreen controls and guided setups.

– Online communities and forums provide support. Users can find troubleshooting guides, sharing experiences, and advice from fellow enthusiasts.

Versatility:

– Large build volumes allow for the creation of sizeable projects. For instance, printers like the Creality CR-10 series feature print areas over 300 mm³, useful for larger models and prototypes.

– Compatibility with various materials expands design options. Hobbyists can choose from plastics like PLA, PETG, or flexible filaments, depending on their needs.

High-quality output:

– Precision and resolution are crucial aspects. High-end models can achieve layer resolutions as fine as 50 microns, enabling smooth surfaces and intricate details.

– Advanced print technologies, such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), deliver different printing styles. Users can select a method based on specific project requirements.

Affordability:

– Competitive pricing makes these printers accessible. Many good quality large 3D printers are available for under $1,000, making them a feasible option for hobbyists.

– Ongoing costs, such as materials and maintenance, are often stable, allowing for budget-friendly projects and experimentation.

Innovative features:

– Safety features, such as automatic shut-off and filament sensors, add security during the printing process. Users can feel confident when leaving their machines unattended.

– Connectivity options, including Wi-Fi, USB, and SD card support, provide flexibility in how projects can be initiated and managed.

These qualities demonstrate how the best 3D large printers effectively support hobbyists and enthusiasts in their creative pursuits and project realizations.

What Essential Factors Should You Consider When Selecting the Best 3D Large Printer for Your Business?

To select the best 3D large printer for your business, consider factors such as printing technology, print volume, material compatibility, resolution, reliability, and cost.

- Printing Technology

- Print Volume

- Material Compatibility

- Resolution

- Reliability

- Cost

Understanding these factors is crucial for making an informed decision on a 3D large printer.

1. Printing Technology:

Printing technology defines how a 3D printer creates objects from a digital file. Common technologies include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). FDM is widely used for its affordability and ease of use. According to a 2019 report by Gartner, FDM printers accounted for 75% of the market share. SLS offers better strength and accuracy but at a higher cost.

2. Print Volume:

Print volume refers to the maximum size of an object that a printer can produce. A larger print volume allows for the creation of bigger prototypes or parts in one piece, reducing assembly time. For example, a printer with a volume of 1,000 x 1,000 x 1,000 mm is ideal for large projects. Businesses often evaluate their specific requirements to determine the necessary dimensions.

3. Material Compatibility:

Material compatibility focuses on the types of materials a printer can use effectively. Common materials include thermoplastics, resins, and metals. A versatile printer that can handle multiple materials opens up more design possibilities. For instance, some industrial printers are capable of using both plastic and metal filaments, enhancing functionality.

4. Resolution:

Resolution defines the printer’s ability to produce detailed and accurate models. Higher resolution results in smoother finishes and finer details. For example, a printer with a resolution of 50 microns can produce significantly more details than one with 200 microns. Businesses requiring fine details for presentations or prototypes should prioritize higher resolution capabilities.

5. Reliability:

Reliability reflects how consistently a printer can operate without issues. A reliable printer minimizes downtime and ensures continuous production. Maintenance records and customer reviews can provide insights into a printer’s reliability. According to a survey conducted by 3D Hubs, users often prefer printers known for consistent performance over those with advanced features but low reliability.

6. Cost:

Cost includes both the initial purchase price and the operational expenses associated with running the printer. While it can be tempting to go for cheaper models, ongoing costs for materials, maintenance, and energy usage must also be considered. A comprehensive understanding of the total cost of ownership (TCO) can lead to better budget planning and resource allocation in the long run.

How Do Costs for the Best 3D Large Printers Vary Among Different Models?

Costs for the best 3D large printers vary significantly among different models due to factors such as printing technology, build volume, material compatibility, and brand reputation.

Printing technology: Large 3D printers typically use technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS). For example, FDM printers are generally less expensive, often ranging from $1,000 to $5,000, while SLS printers can cost between $20,000 and $100,000 due to their complexity and material costs (DePaul, 2022).

Build volume: The size of the printable area directly influences the printer’s cost. Larger printers with bigger build volumes can range from $5,000 to $50,000. According to research by Smith (2023), printers capable of producing objects over 1 meter in height significantly add to the investment required.

Material compatibility: Different 3D printing technologies support various materials, such as plastics, metals, and composites. Printers that handle specialty materials often command higher prices. For instance, a printer compatible with advanced materials like carbon fiber may cost upwards of $10,000 (Johnson, 2023).

Brand reputation: Established brands in the 3D printing industry may charge more for their printers due to perceived reliability and customer support. High-end models from reputable brands can reach prices exceeding $30,000, reflecting their proven technology and customer service commitment (Harris, 2023).

Additional features: Extras such as multi-material printing, enclosed build chambers, and advanced software capabilities can also affect costs. High-end models with these features often range from $15,000 to $80,000 (Lee, 2023).

With these factors influencing the price, prospective buyers need to consider their specific needs and budget when selecting a 3D large printer.

What Future Trends Are Emerging in Large 3D Printing Technology?

The future trends emerging in large 3D printing technology include advancements in materials, faster printing speeds, integration with AI, and increased sustainability practices.

- Advancements in materials

- Faster printing speeds

- Integration with artificial intelligence (AI)

- Increased sustainability practices

- Customization and personalization

- Multi-material printing capabilities

- Expansion into new industries, such as construction and aerospace

The following sections will provide detailed explanations of each trend related to large 3D printing technology.

-

Advancements in materials: Advancements in materials in large 3D printing technology involve the development of new print materials that enhance durability and flexibility. This trend includes the use of composites and biomaterials. For instance, a study by Würth et al. (2022) highlighted the application of carbon fiber-reinforced polymers, which improve strength-to-weight ratios. Companies like BASF are investing in such materials to create stronger, lighter, and more versatile printed components.

-

Faster printing speeds: Faster printing speeds in large 3D printing technology refer to the ability to produce larger and more intricate objects in less time. Techniques like Continuous Liquid Interface Production (CLIP) developed by Carbon 3D significantly reduce print times while maintaining quality. Research by Prius et al. (2023) demonstrated that CLIP can print components up to 100 times faster than traditional methods, making it viable for mass production.

-

Integration with artificial intelligence (AI): Integration with AI in large 3D printing technology enhances design optimization and process efficiency. AI algorithms can analyze and improve print parameters in real-time, resulting in fewer print errors and material wastage. For example, startup companies like nTopology are using AI to create optimized designs that minimize material usage while ensuring structural integrity.

-

Increased sustainability practices: Increased sustainability practices focus on minimizing environmental impact in 3D printing. This trend includes the use of recycled materials and energy-efficient processes. Companies like Eco3D are pioneering the use of recycled plastics in large-scale prints, aiming to reduce plastic waste. The Ellen MacArthur Foundation noted that sustainable 3D printing could significantly reduce carbon emissions when produced using renewable energy sources.

-

Customization and personalization: Customization and personalization in large 3D printing allow for tailored products that meet individual needs. This trend is especially prevalent in industries like healthcare, where prosthetics can be printed to specific patient anatomy. As reported by the Journal of Biomechanics, personalized prosthetic limbs enhance comfort and functionality, leading to better user outcomes.

-

Multi-material printing capabilities: Multi-material printing capabilities enable the creation of complex structures that combine different materials in a single print. This trend enhances functionality and performance in one object. For instance, the University of Cambridge showcased how multi-material 3D printing can produce soft robotics that can perform intricate tasks by combining rigid and flexible materials in a single printing run.

-

Expansion into new industries, such as construction and aerospace: Expansion into new industries, like construction and aerospace, exemplifies the versatility of large 3D printing. Companies like ICON are using large 3D printers to construct affordable housing rapidly. In aerospace, firms like Boeing are adopting 3D printing for lightweight components that enhance fuel efficiency and reduce manufacturing costs. Reports indicate that the aerospace sector could save nearly $3 billion by integrating 3D printing in production processes by 2030.